■ Product Overview

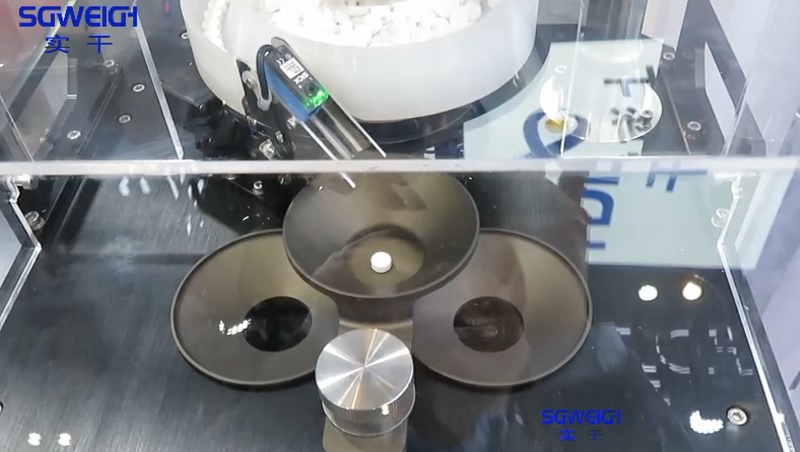

The Tablet Sampling Checkweigher is a precision checkweighing device specifically designed for tablet sampling and weighing in the pharmaceutical industry. It is used for timed or quantitative sampling and weighing of tablets produced by automatic tablet compressors.

The Sampling Checkweigher for Laboratory can automatically complete sampling, weighing, recording, and data tracking, enabling real-time monitoring of weight consistency and tablet compression stability during the tablet production process. It is widely used in GMP production lines in pharmaceutical plants.

■ Tech Specifications

1.It can detect all types of capsules such as 000#, 00#, 0#, 1#, 2#, 3#, 4#, 5#, SA, SB, and conventional tablets.

2.Weighing range:0-2000mg.

Output:up to 60 pcs / min

Highest accuracy:±1mg(Depend on products)

3.Power supply:220V,50HZ.

4.7-inch resistive touch screen.

5.One-touch automatic calibration function, built-in E-grade stainless steel weights.

6.Support communication interfaces RS-232, RS485, Mudbus-TCP communication protocols, USB and Ethernet.

7.Automatic cleaning at startup, manual zeroing, data clearing.

8.Sensor overload protection, AD separation mode.

9.The material contact part is stainless steel, or hardened anti-corrosion treatment, which will not cause drug contamination.

10.Sudden power failure self-protection to prevent data loss.

11.Counting function, timely understanding of the weighing quantity.

12.Support power supply voltage customization to meet foreign power supply.

■ Main Features

1.High-precision weighing

Equipped with a high-precision weighing sensor, it can accurately measure the weight of a single capsule with an accuracy of up to milligram level.

2. Multi-specification weighing

Capsule sampling weighing machine can carry out sampling weighing of capsules or tablets of different specifications after sorting.

3. Permission management

Three-level permission management of the device interface operating system, setting different permissions for different personnel.

4.Automated operation

It can automatically complete the processes of capsule feeding, weighing, sorting and rejecting unqualified products, reducing manual operations and improving production efficiency.

5. Fast detection

With a faster detection speed, it can adapt to high-efficiency production lines to ensure that it does not affect the overall production process.

6. Sorting function

According to the preset weight standard, the equipment can automatically sort out unqualified capsules (overweight or underweight) from qualified products.

7. Data recording and traceability

Able to record weighing data for easy product quality traceability and statistical analysis.

■ Application

■ Customers

■ Exhibitions

■ Packaging & Delivery

● Our machines undergo comprehensive testing and commissioning before shipment to ensure stable and reliable performance.

● Equipment is packaged in thickened wooden crates with shock and moisture-proof interiors to effectively prevent damage during transportation.

● We partner with several professional international logistics companies and support a variety of shipping methods, including sea, air, and land transport.

● Ensure the equipment arrives safely and on time at your facility.

TAGS