|| Product Introduction

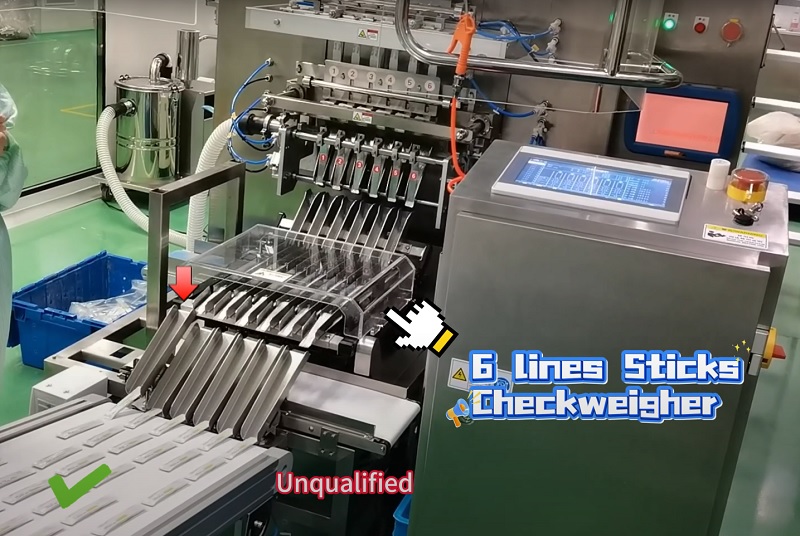

Dynamic Inline Liquid Gel 8 Line Check Weigher is a high-speed, multi-lane industrial system designed to weigh products simultaneously as they move along a production or packaging line.Check Weigher for Sachets and Sticks can handle eight parallel lanes of product.

|| Tech Specifications

Type:SG-8X

Weighing scope:1-50g

Restrictions of product:L:180 W:40 H:2-20(mm)

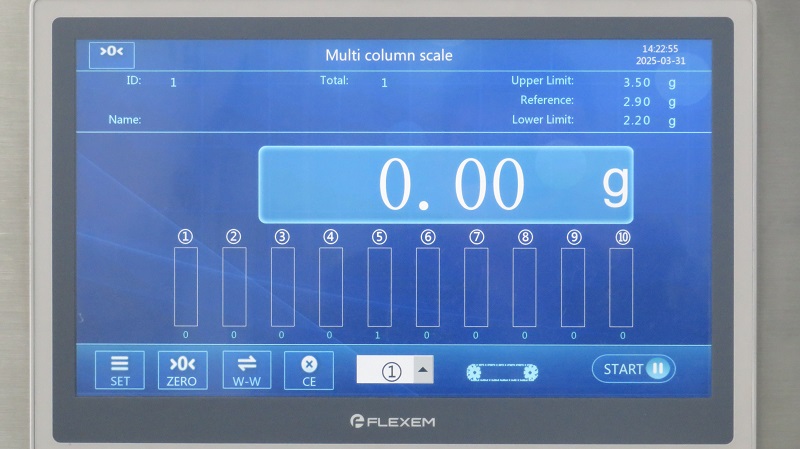

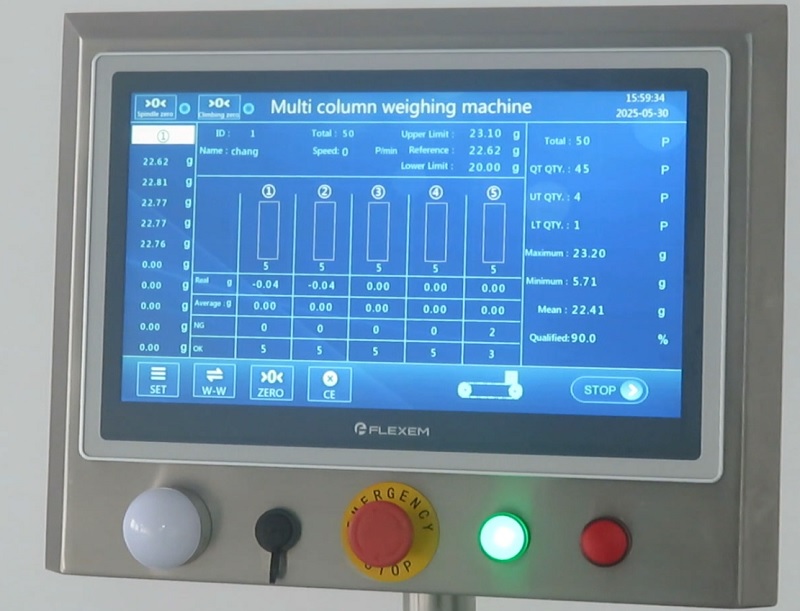

Accuracy:±0.01g (Depends on products)

Division scale:0.01g

Belt width:30mm

Highest speed:70pcs/min(one lane)

Weight of machine:about 200Kg

Powder supply:AC220V 50HZ

Power:about 300W

Main material:SUS304(Stainless Steel)

Multi-channel passing products to improve production efficiency

(the number of channels can be customized)

|| Main Features

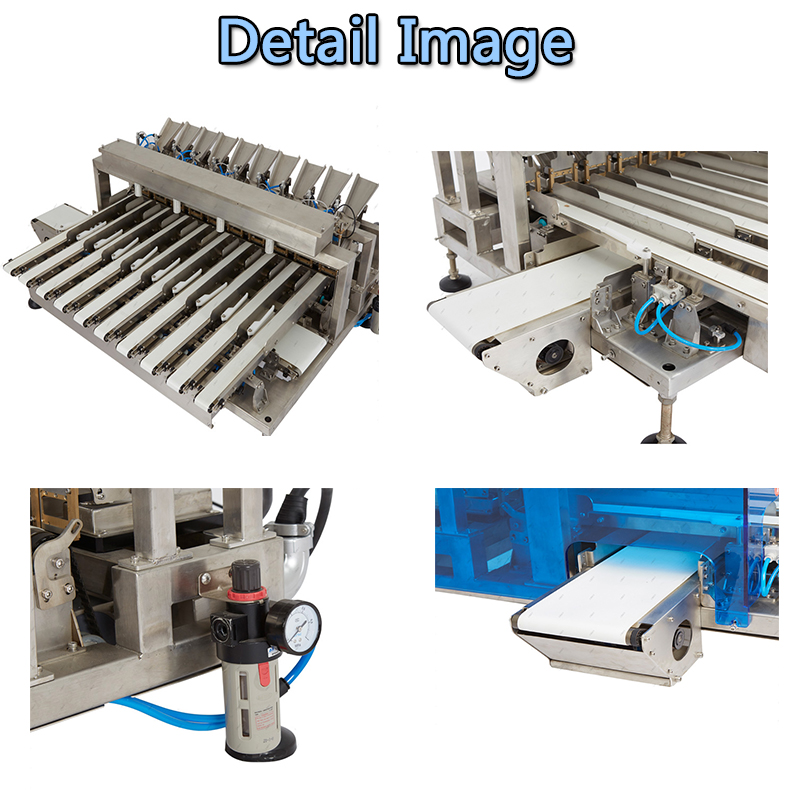

1.Infeed & Lane Diverting System: Gently distributes products into eight distinct lanes.

2.Eight Independent Weigh Platforms: Each lane has its own high-precision load cell for simultaneous weighing.

3.High-Speed Conveyor Belts: Designed for stability and minimal vibration to ensure weighing accuracy.

4.Rejection System (x8): Each lane typically has its own dedicated, high-speed rejector to handle rejects without affecting adjacent lanes.

5.Control Cabinet & Software: The brain of the system. The software allows for easy setup of weight parameters, displays real-time data, and generates reports. It often features SPC (Statistical Process Control) capabilities.

|| Application

Pharmaceuticals: Blister packs and sachets.

Food & Beverage: Candy, snacks, tea bags, coffee pods, condiment sachets, and small packaged goods.

Cosmetics & Personal Care: Small bottles, tubes, lipstick, and sample sachets.

|| Our Customers

|| Our Exhibitions

|| Package & Shipping

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.

|| FAQ

|| FAQ

Q1. Are you a manufacturer or a trader?

A: Shanghai Shigan Industrial Co., Ltd. is a manufacturer located in Shanghai,China. We have our own product design team and factory.

Q2. How many types of checkweighers do you have?

A:Our company has a variety of models of checkweighers, suitable for most products and can be applied to almost all industries. Our company’s checkweighers can be customized according to demand.We have standard checkweighers, bottle checkweighers, multi-lane checkweighers,tablet capsule checkweighers, box checkweighers,heavy object checkweighers and so on.

Q3. What factors should be considered when choosing a checkweigher?

What is the product you want to weigh?

How many grams/kg of the product?

What is the size of the product?

What are the speed requirements?

Accuracy requirements?

Based on the above information, our sales will recommend the most suitable checkweigher for you.

Q4. What kind of shipping methods can you provide?

A: Sea, air and international express. We will send photos and videos of the machine to customers before delivery to check the operation of the machine.

Q5. Do you accept customer logos and customizations?

A: We accept all kinds of customization and logos for all products.

Q6. How is the product packaging?Is it easy to be damaged during transportation?

A: No. We use wooden boxes, which are very safe.

TAGS

SG-DJ10 Automatic Sampling Checkweigher (mg)

Glass Bottle Turntable Checkweigher

2 Lines Bag Box Stick Checkweigher

Automatic Conveyor Pet Food Packaging Metal Detector

High Throughput Advanced Pharma Metal Detectors

Bulk Materials Vertical Free Fall Metal Detector