■ Product Introduction

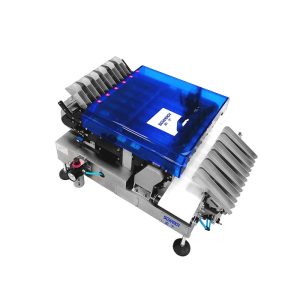

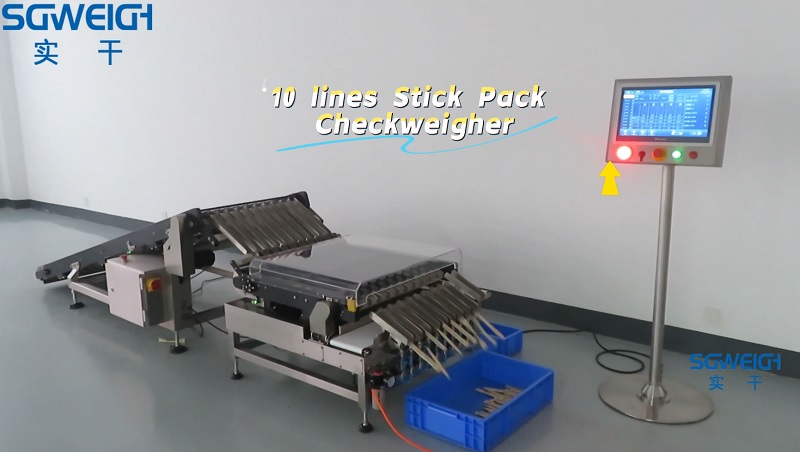

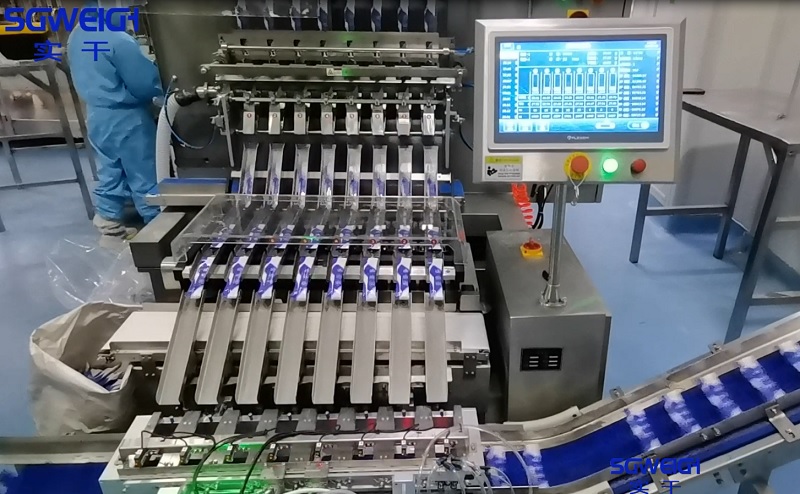

The 10-Track Conveyor Checkweigher is a high-efficiency automatic weighing system designed for simultaneous multi-lane product weight inspection in high-speed production lines. Multi lane Stick Check Weigher provides precise and independent weighing for up to 10 parallel tracks, ensuring maximum throughput and reliable quality control for small packages or individual items.

■ Tech Specifications

Model:SG-10X

Weighing Range:1-50g

Accuracy: 0.01 gram (depending on the product)

Sorting Speed:40-60pcs/min (one lane)(depending on the length of the product)

Conveying Speed:20-100m/min

Operation Method:Touch operation

Conveying Direction:Can be placed according to the actual situation on site

Elimination Method:Lifting Rejection

Belt Height From The Ground:450±50mm (can be customized according to customer requirements)

Machine Structure:Stainless steel (SUS304)

Power Supply:220V 50-60HZ

Power:About400W

Windshield:Thick acrylic (to avoid airflow interference)

■ Main Features

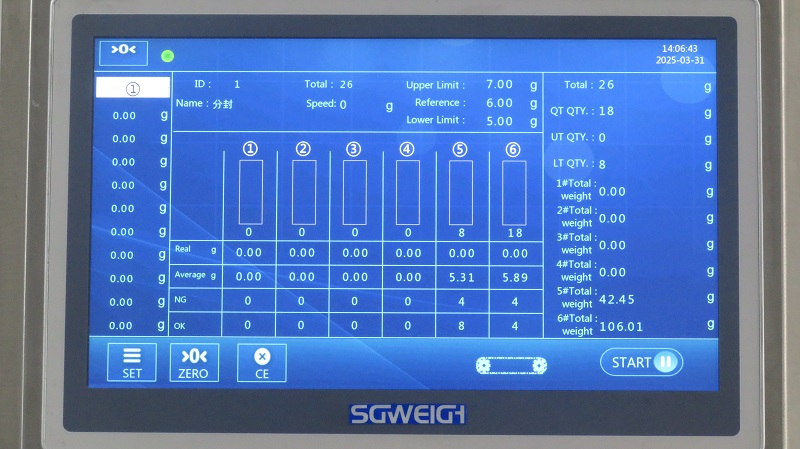

1.High-Speed Multi-Lane Weighing

Each of the 10 weighing lanes operates independently, allowing real-time weight inspection without interference.

Ideal for stick packs, sachets, capsules, small pouches, and other small-format products.

2.High Precision & Stability

Equipped with high-resolution load cells and an advanced digital filtering system, ensuring consistent accuracy even at high speeds.

Automatic zero tracking and dynamic compensation functions maintain stable performance over time.

3.Compact Multi-Track Design

Space-saving layout integrates 10 lanes in a single compact frame.

Can be directly connected to multi-lane packaging machines for seamless inline operation.

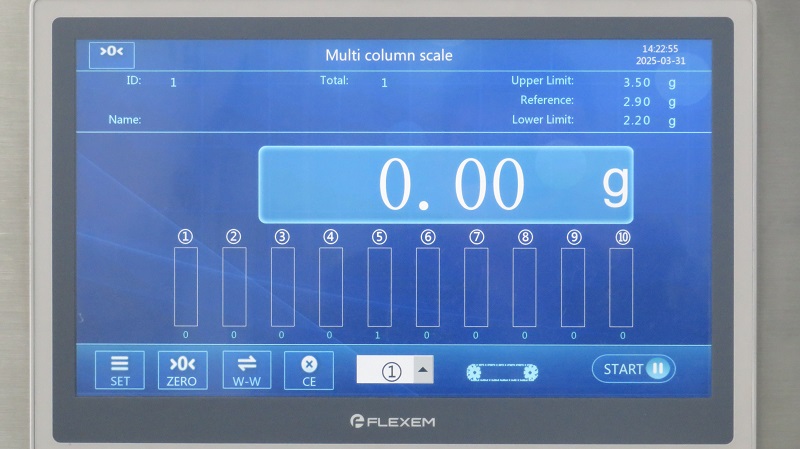

4.User-Friendly Operation

10-inch touch screen with intuitive interface for easy parameter setting and data monitoring.

Supports product recipe storage, fast product changeover, and multi-language display.

5.Smart Data Management

Built-in data recording and export functions for production traceability.

Optional Ethernet or USB connection for remote monitoring and statistical analysis.

6.Flexible Reject Options

Each lane is equipped with independent rejection devices such as a drop flap.

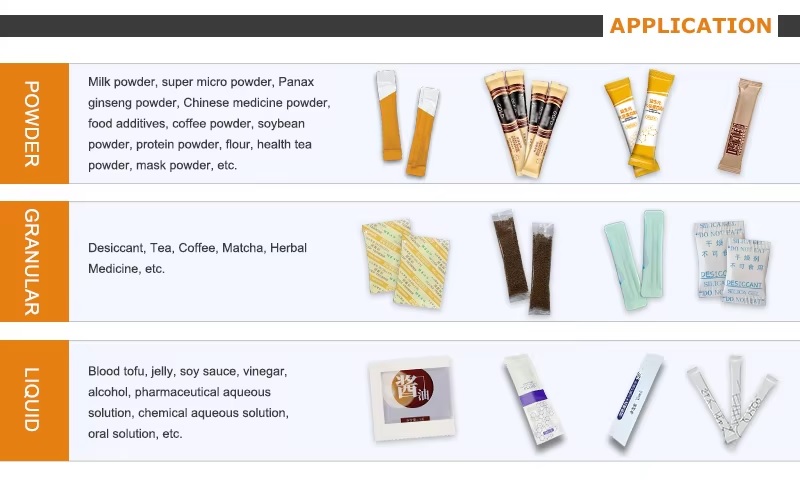

■ Application

■ Customers

■ Exhibitions

■ Packaging & Delivery

● Our machines undergo comprehensive testing and commissioning before shipment to ensure stable and reliable performance.

● Equipment is packaged in thickened wooden crates with shock and moisture-proof interiors to effectively prevent damage during transportation.

● We partner with several professional international logistics companies and support a variety of shipping methods, including sea, air, and land transport.

● Ensure the equipment arrives safely and on time at your facility.

TAGS

Best Pharmaceutical Metal Detector for Tablets and Capsules

Tablets Metal Detector Connected to Tablet Press

Industrial Conveyor Metal Detector

Vertical Fall Chips Metal Detector System for Powder Granule

High Accuracy Conveyor Check Weigher Metal Detector