■ Product Overview

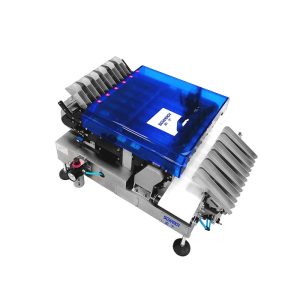

The High Speed Sachet 6 Lane Dynamic Check Weigher is an online dynamic weighing device used in high-speed, multi-channel production lines. It is suitable for 100% weight inspection of products with large production capacity, small specifications, or regular arrangement.The Multi-Line Stick Packs Weight Checker operates synchronously through six independent weighing channels, achieving accurate judgment and automatic rejection of product weights without reducing production line speed.

■ Tech Specifications

Type:SG-6X

Weighing scope:1-200g

Restrictions of product:L:180 W:40 H:2-20(mm)/customizable

Accuracy:±0.01g (Depends on products)

Division scale:0.01g

Belt width:30mm(customizable)

Speed:40-60 pcs/min(one lane)

Weight of machine:about 200Kg

Powder supply:AC220V 50HZ

Power:about 300W

Main material:SUS304(Stainless Steel)

Multi-lane passing products to improve production efficiency

(the number of channels can be customized)

■ Main Features

1. Six Independent Weighing Channels

Each column is equipped with a high-precision weighing sensor, ensuring stable simultaneous detection across multiple channels without interference.

2. High-Speed Dynamic Weighing

Supports continuous operation of high-speed production lines and is suitable for integration with multi-column packaging machines, vertical packaging machines, and strip packaging machines.

3. High-Precision Weight Judgment

Accurately identifies overweight and underweight products in real time, ensuring product consistency and compliance.

4. Automatic Non-Conforming Product Rejection System

Multiple rejection methods are available, including slide rails and lifting mechanisms, adaptable to different product forms.

5. Intelligent Control and Data Management

Equipped with a touchscreen operating interface, supporting parameter and formula storage, weight statistics, trend analysis, and report export.

6. Modular Structure Design

Easy to clean, maintain, and upgrade, suitable for industrial environments requiring long-term continuous operation.

7. Connectable to Upstream/Downstream Equipment

Supports integration with packaging machines, metal detectors, vision inspection systems, and other equipment.

■ Application

■ Customers

■ Exhibitions

■ Packaging & Delivery

● Our machines undergo comprehensive testing and commissioning before shipment to ensure stable and reliable performance.

● Equipment is packaged in thickened wooden crates with shock and moisture-proof interiors to effectively prevent damage during transportation.

● We partner with several professional international logistics companies and support a variety of shipping methods, including sea, air, and land transport.

● Ensure the equipment arrives safely and on time at your facility.

Tags