■ Product Overview

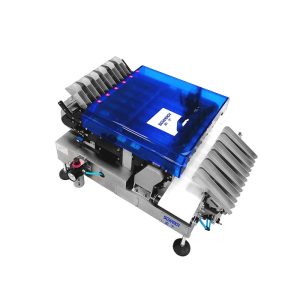

The Food Snack Production Line Conveyor Metal Detector is a highly sensitive online detection device used at the end of a food production line or at critical control points to accurately identify iron (Fe), non-ferrous (Non-Fe), and stainless steel (SUS) metal foreign objects mixed in with food. The Metal Detector with Auto Rejection employs advanced multi-frequency digital signal processing (DSP) technology and an automatic product effect compensation algorithm to maintain stable detection performance and ensure food safety.

■ Tech Specifications

Type:SG-M400

Machine Grade:Food Grade

Detect method:Electromagnetic wave detection

Detecting width:150-1000mm customized according to requirements

Detecting height:80-500mm (or custom-made)

Detecting sensitivity:Fe 0.8mm, Non-Fe1.5mm, SUS 1.5mm

Detecting adjustment:Intelligent adjustable

Belt Speed:25m /min (or specified)

Alarm mode:The buzzer alarm, the motor automatically stop

Power:AC220V,50/60Hz (Or Customized)

■ Main Features

1. High-Sensitivity Metal Foreign Object Detection: Accurately identifies metallic foreign objects such as iron (Fe), non-ferrous metals (Non-Fe), and stainless steel (SUS) mixed in food. Sensitivity can be adjusted according to product type.

2. Automatic Rejection System: Configurable with multiple rejection methods including air blowing, lever-type, flip-plate, and drop-type, enabling automatic separation of defective products without affecting production line continuity.

4. Real-Time Alarm and Recording Function: Automatically triggers audible and visual alarms upon detection of metallic foreign objects. Simultaneously, the system records detection time, product name, rejection count, and other data for easy quality traceability.

5. User-Friendly Human-Machine Interface: Equipped with a touchscreen interface, allowing quick setting of parameters such as sensitivity, belt speed, and formula. Supports both Chinese and English operation.

6. Self-Test and Automatic Calibration Functions: The system features self-test upon startup, fault diagnosis, and automatic calibration functions to ensure long-term stable detection performance.

8. Adaptable to various food forms. Suitable for different types of food such as bulk, bagged, bottled, palletized, and boxed foods, and can be seamlessly connected with conveyor lines, packaging machines, and weighing equipment.

■ Application

■ Customers

■ Exhibitions

■ Packaging & Delivery

Our machines is fully tested and calibrated before delivery.

It is packed in a strong wooden case with internal shockproof protection.

Various shipping options are available — by sea, air, or land — ensuring safe and on-time delivery by professional logistics partners.

TAGS

CE Checkweigher for Capsule Production Line

2-Track Blister Stick Checkweigher

Small Size Tablet Sampling Checkweigher

Metal Detector for Capsules Tablets APIs

Inline Production Combi Metal Detector and Checkweigher