|| Product Introduction

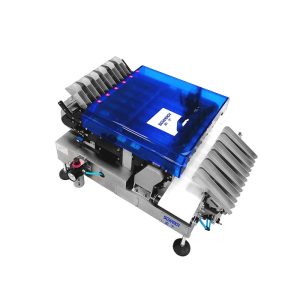

Dynamic Checkweigher combines hygienic design with flexibility and maximum performance. It was developed in accordance with the strict hygienic design guidelines for production packaged food products. A wide range of configuration options covers practically every requirement.

High Accuracy Checkweigher can help you eliminate overweight or underweight products so that standard-weight products can reach every customer, which not only avoids increasing costs due to overweight but also avoids offending consumers due to underweight.

|| Tech Specifications

Model:SG-150

Weighing range:5-500g

Minimum scale:0.1g

Checking speed :Max 120pcs/Min

Belt speed:0-65m/min

Box size limit:Length:200mm Width:150mm Height:3-200mm

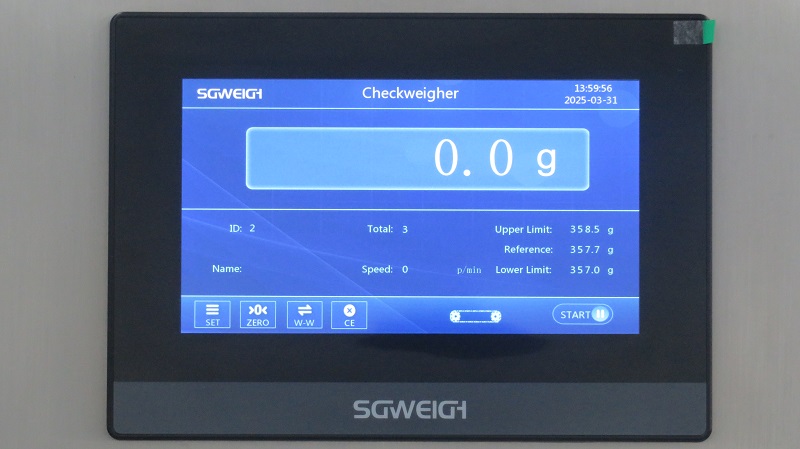

Operation Way:Touch operation

Conveying direction:Facing the touch screen from left to right

Rejection method:Push Rejection

Belt height from the ground:750±50mm(can be customized)

Machine material:Stainless steel(SUS304)

Power supply:220V50/60HZ

Power:About300W

Feeding conveyor size:316mmX150mm

Weighing conveyor size:316mmX150mm

Rejection conveyor size:510mmX150mm

Weight:About120KG

Windshield:8mm Thick acrylic (to avoid airflow interference)

Feet M20 stainless steel with shock-absorbing rubber pad

External air source:0.2-0.6Mpa Air pressure port:Φ8mm

|| Main Features

1. Online Dynamic Weighing

Achieves real-time automatic weighing of products as they pass at high speed on the conveyor belt, without machine downtime or manual intervention, ensuring uninterrupted continuous production lines.

2. Automatic Rejection of Defective Products

Automatically identifies overweight, underweight, and missing parts of products within a set weight range and quickly rejects them using rejection devices (push rod, air blowing, lever, drop type, etc.), preventing defective products from entering the next process.

3. Full Inspection Ensures Consistent Quality

Each product is inspected individually to ensure weight compliance in the packaging, food, pharmaceutical, and daily chemical industries, reducing the risk of human error.

4. Data Recording and Tracking

Automatically records inspection data, including weight, batch, production time, and pass rate, and can interface with MES/ERP systems for traceability and production data management.

5. Production Line Alarms and Linkage

Issues audible and visual alarms when consecutive defects occur or equipment malfunctions. Can be linked with upstream and downstream equipment to automatically pause or stop the production line, ensuring production safety.

6. Multiple Interfaces and Parameter Settings

The touchscreen interface supports switching between multiple product formulas, setting upper and lower weight limits, and viewing historical records, making it easy for users to manage.

7. Strong Applicability to Different Scenarios

It can be used with various conveyor systems, such as flat belt conveyors, roller conveyors, lifting conveyors, and inclined conveyors, and can be integrated with filling machines, packaging machines, sealing machines, and other equipment.

|| Application

|| Our Customers

|| Our Exhibitions

|| Packaging & Delivery

● Our machines undergo comprehensive testing and commissioning before shipment to ensure stable and reliable performance.

● Equipment is packaged in thickened wooden crates with shock and moisture-proof interiors to effectively prevent damage during transportation.

● We partner with several professional international logistics companies and support a variety of shipping methods, including sea, air, and land transport.

● Ensure the equipment arrives safely and on time at your facility.

TAGS

High-Speed Online Dynamic Vial Checkweigher

CE Checkweigher for Capsule

2-Track Blister Stick Checkweigher

Multi lane Conveyor Checkweigher (10 Track)

4-Line Dynamic Check Weigher