■ Product Overview

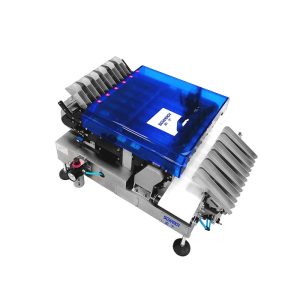

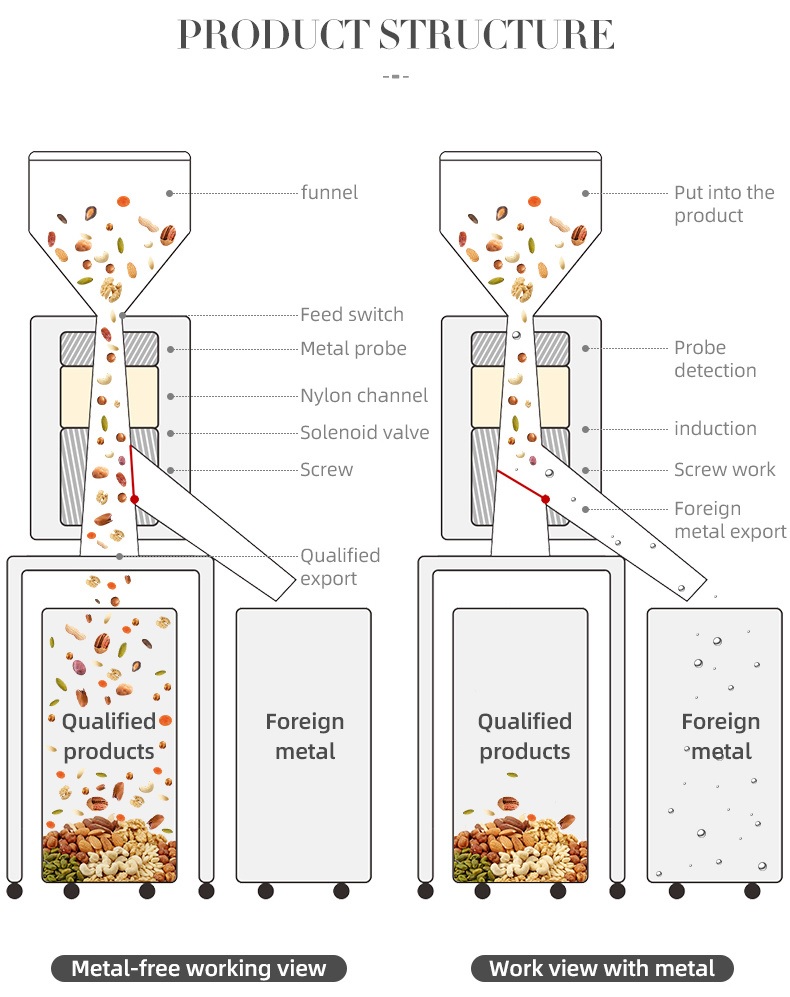

Vertical Fall Pipe Metal Detector is a type of vertical metal detection equipment primarily used to detect metal impurities mixed in with freely falling powdery, granular, or bulk products. The product falls naturally through the detection channel by gravity, and the system detects and determines in real time whether it contains metal foreign objects. This structure is commonly found in industries such as food production, feed, chemicals, and pharmaceuticals.

Gravity Fed Metal Detection for Bulk Items can detect metal contaminants in bulk raw materials before packaging or during processing, preventing damage to subsequent production machinery or the entry of substandard products into the market.

■ Tech Specifications

Name:Gravity-Fed Metal Detector

Detection sensitivity: Fe: 0.4mm, stainless steel: 0.6mm

Throughput:300kg-3000kg

Material of Construction: 304 Brushed stainless steel

Product:Pre-packaged, free-flowing products

Parameter Adjustment:Auto or manual programming

Alarm Model:Auto rejection diversion flap

IP Rating:65

■ Main Features

1. Suitable for bulk/powdered/granular product testing

It can test free-fall products such as grains, cereals, powders, dried fruits, and granules, with stable testing results.

2. High sensitivity detection capability

It can detect ferrous, non-ferrous metals, and stainless steel residues, and can detect small metal impurities.

3. Modular and easy-to-maintain structure

The vertical design saves space and can be integrated into vertical packaging machines, elevators, under hoppers, etc.; the structure is easy to clean and maintain.

4. Automation and digital control

It supports automatic product learning, storage of multiple settings, networking, and integration with production control systems.

■ Application

■ Customers

■ Exhibitions

■ Packaging & Delivery

Our machines is fully tested and calibrated before delivery.

It is packed in a strong wooden case with internal shockproof protection.

Various shipping options are available — by sea, air, or land — ensuring safe and on-time delivery by professional logistics partners.

TAGS

Inline Dual-lane Checkweigher

Heavy Packaging Industrial Checkweigher

Clamping Type Cosmetic Oral Liquid Bottle Containers Checkweigher

High Speed Sachet 6 Lane Dynamic Check Weigher

Laboratory Automatic Hard Gelatin Capsule Weight Sampling System

Capsule Metal Detector – 0.3mm High Sensitivity

Tablets Metal Detector After Capsule Filling Machine

Vertical Drop Metal Detector for Bulk Food