■ Product Overview

The Capsule Metal Detector is a high-precision inspection system designed to detect and eliminate metal contaminants from capsules during high-speed production.Capsules and Tablets Metal Detection Machine ensures product purity, process stability, and consistent quality control in automated manufacturing environments.

■ Tech Specifications

Type:SG-M50

Inlet height: 770-930mm Port size: 76mm

Outlet Height: 770-860mm Port size: 51mm

Effective passing size: W70*H20mm

Maximum production capacity: 500,000 pcs/hour

Sensitivity(adjustable or not):Yes

Detection sensitivity: Fe: 0.3mm, SUS: 0.5mm,Non-Fe:0.5mm

Operation Mode:Touch Screen/LED fast key input

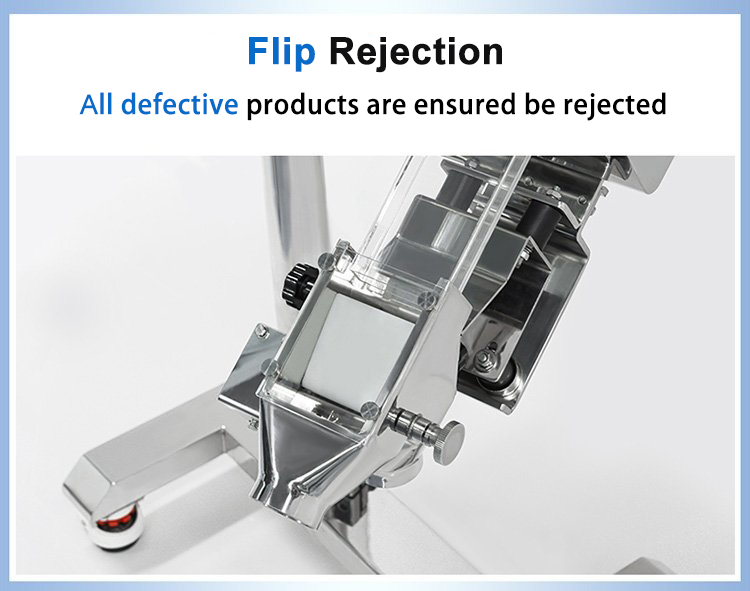

Removal method: flip culling

Working voltage: 220V/110V, 50/60HZ

Equipment dimensions: 1115*550 (1280-1400) mm

Note: The above sensitivity is when the test block freely falls through the detection pipeline. The actual detection sensitivity may vary due to different product characteristics or working environments,it should be based on the actual detection sensitivity.

■ Main Features

1.High Sensitivity Metal Detection

Equipped with advanced balanced coil technology and digital signal processing, the capsule metal detector can reliably identify ferrous, non-ferrous, and stainless steel contaminants, even at extremely small sizes. Stable detection performance is maintained despite product effect or environmental interference.

2.Optimized for Capsule Applications

The detection head and conveyor structure are specifically engineered for capsules, ensuring smooth product flow without damage or blockage.

3.Automatic Rejection System

When metal contamination is detected, the system activates a high-speed automatic rejection mechanism, accurately separating affected capsules without interrupting continuous operation. This minimizes product loss and improves overall efficiency.

4.User-Friendly Operation and Control

An intuitive touchscreen interface allows operators to easily set sensitivity levels, monitor real-time detection status, and review inspection data. Multi-level access management helps prevent unauthorized parameter changes.

5.Robust Construction for Continuous Operation

Manufactured with durable materials and precision components, the capsule metal detector is suitable for long-term, high-speed production lines. Its compact footprint allows easy integration into existing processing or packaging systems.

■ Application

■ Customers

■ Exhibitions

■ Packaging & Delivery

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.

TAGS

Heavy Packaging Industrial Checkweigher

Clamping Type Cosmetic Oral Liquid Bottle Containers Checkweigher

High Speed Sachet 6 Lane Dynamic Check Weigher

Laboratory Automatic Hard Gelatin Capsule Weight Sampling System

High-speed Pharmaceutical Capsule Automatic Weight Inspection

Bottled Tablets Capsules Rotary Checkweigher