|| Product Introduction

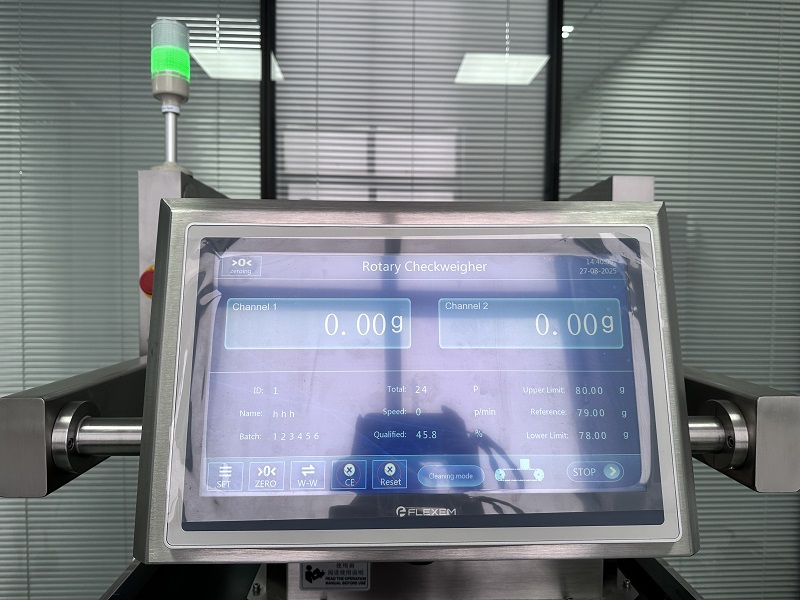

The Bottled Tablets Capsules Rotary Checkweigher is a high-precision dynamic weighing device specifically designed for bottled solid and liquid dosage forms in the pharmaceutical industry. The equipment employs a multi-station rotary structure, enabling continuous, high-speed, and stable online weighing within a limited space. It is particularly suitable for glass bottle packaging production lines for tablets, capsules, granules, and oral liquids.

Through independent weighing stations and a stable guiding structure, this checkweigher effectively reduces the swaying and vibration of glass bottles during transport and weighing, ensuring excellent weighing repeatability even at high speeds.

The Liquid Bottle Weight Inspection Machine can automatically detect underweight or overweight defective products and accurately reject them using air blowing, levers, or diversion methods, meeting the stringent requirements of pharmaceutical companies for dosage control and quality traceability.

|| Tech Specifications

Model: SG-Z2 (dual channel)

Weighing range: 5-300g

Minimum scale: 0.01g

Sorting accuracy: ±0.02 grams (depending on the product)

Sorting speed: maximum 50 pieces/minute (single channel)

Conveying speed:0-50m/min

Operation mode: touch operation

Conveying direction: Facing the touch screen from left to right

Rejection method: air blowing removal/push plate removal

Belt height from the ground: 750±50mm (can be customized according to customer requirements)

Machine structure: stainless steel (SUS304)

Power supply: 220V 50-60HZ

Power: about 1500W

Windshield: thick acrylic (to avoid airflow interference)

|| Main Features

1. Multi-station rotary structure, saving production line space.

2. Designed specifically for various bottle types, high stability.

3. High-precision dynamic weighing, suitable for high-speed production.

4. Automatic rejection and statistics of defective products.

5. Meets GMP pharmaceutical manufacturing requirements.

|| Application

|| Our Customers

|| Our Exhibitions

|| Packaging & Delivery

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.

TAGS