■ Product Overview

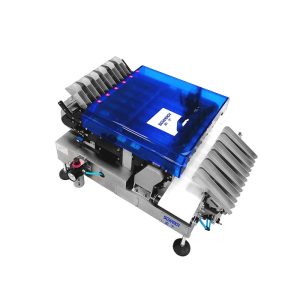

Bottle Checkweighers are high-precision online quality control devices used in the pharmaceutical, health product, cosmetic, and food and beverage industries. Based on traditional dynamic checkweighers, they integrate an intelligent clamping (holding/fixing) system, specifically designed for stable transport and accurate weighing of containers in high-speed production lines carrying irregularly shaped or easily tipped bottles.

■ Tech Specifications

Type:SG-100HH

Weighing scope:2-500g

Restriction of product:L:100 W:100 H:2-150(mm)

Accuracy:±0.01g(Depends on products)

Division scale:0.01g

Highest speed:450pcs/min(Depends on products)

Belt width:100mm

Belt Speed:0-120m/min

Weight of machine:about 120kg

Power supply:AC220V±10%50HZ

Power:about 200W

Main material:SUS304

■ Main Features

1. Intelligent Clamping System

Utilizing an electric clamping mechanism, the system automatically and gently securely holds the bottles in the weighing section, eliminating weighing errors caused by bottle shaking, tipping, or vibration, ensuring measurement stability and repeatability.

2. High-Precision Weighing Module

Equipped with a high-sensitivity sensor and filtering algorithm, it effectively isolates production line vibration interference, achieving high-speed dynamic weighing (up to 60-400 bottles/minute).

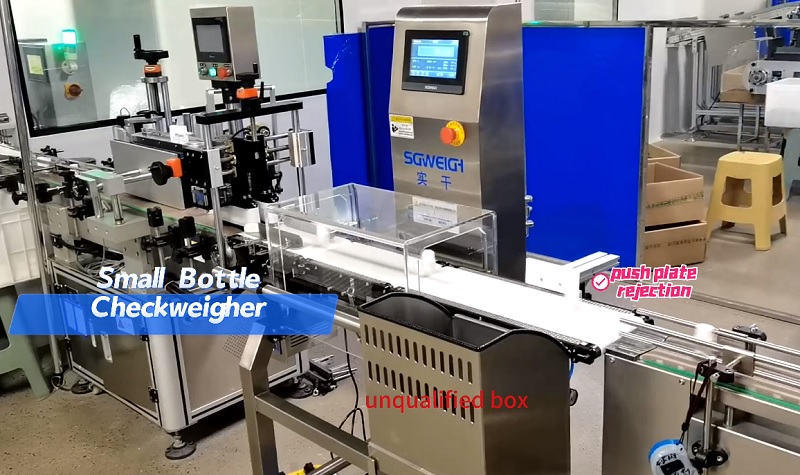

3. Fully Automated Sorting and Feedback Control

Real-time detection of weight deviations (underweight, overweight) automatically triggers the rejection mechanism to remove defective products.

4. Compliance and Traceability

Complies with GMP and other industry standards, providing complete data records and statistical reports to meet the stringent quality audit and traceability requirements of the pharmaceutical industry.

5. Adaptive Design

Modular fixtures can be quickly replaced to adapt to different bottle shapes (round, square, flat, etc.); the stainless steel construction and waterproof design facilitate easy cleaning and are suitable for production in wet or clean environments.

■ Application

Suitable for production lines requiring high stability checkweighing, such as those producing oral liquid bottles, vaccine bottles, perfume bottles, essential oil bottles, beverage bottles, or cans, significantly improving filling accuracy and production efficiency.

■ Customers

■ Exhibitions

■ Packaging & Delivery

● Our machines undergo comprehensive testing and commissioning before shipment to ensure stable and reliable performance.

● Equipment is packaged in thickened wooden crates with shock and moisture-proof interiors to effectively prevent damage during transportation.

● We partner with several professional international logistics companies and support a variety of shipping methods, including sea, air, and land transport.

● Ensure the equipment arrives safely and on time at your facility.

TAGS