■ Product Overview

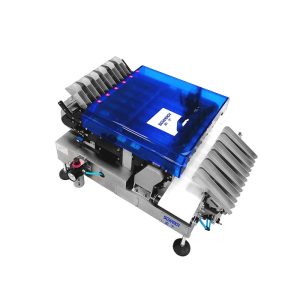

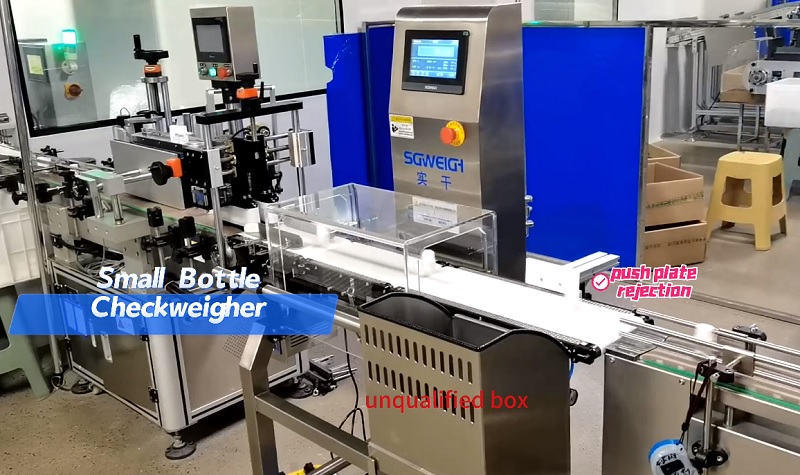

The Bottle Checkweigher is a high-precision automated device designed specifically for online weight detection of bottled products. Its core feature is the addition of a clamping device to the traditional conveyor checkweighing system, which effectively stabilizes the bottle’s posture and ensures accurate and reliable weighing data even in high-speed production environments.

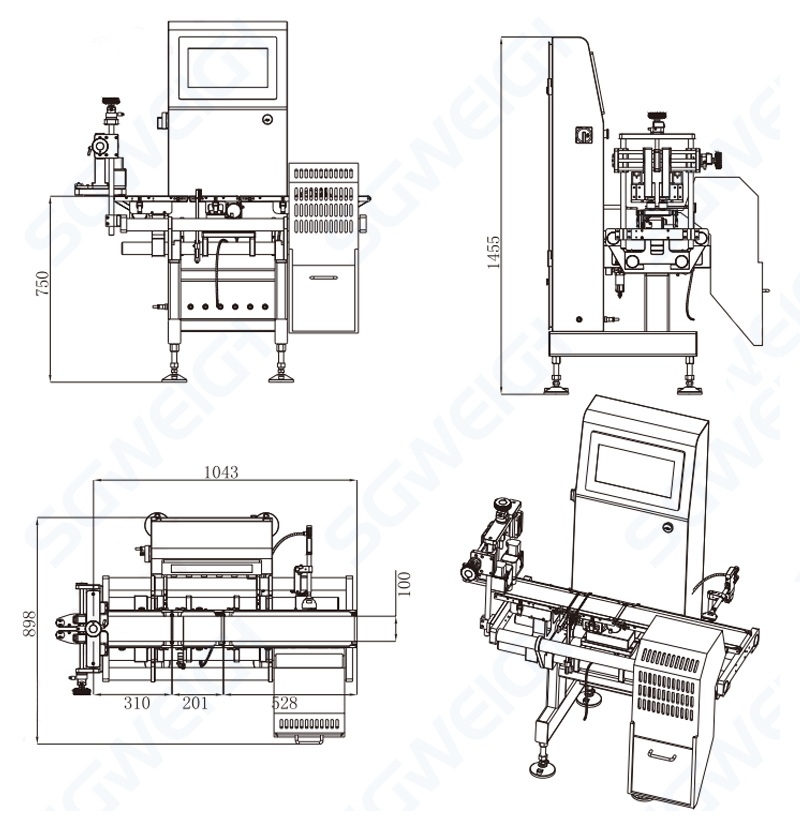

■ Tech Specifications

Type:SG-100HH

Weighing scope:2-300g

Restriction of product:L:100 W:100 H:2-150(mm)

Accuracy:±0.1g(Depends on products)

Division scale:0.01g

Highest speed:450pcs/min(Depends on products)

Belt width:100mm

Belt Speed:0-120m/min

Weight of machine:about 120kg

Power supply:AC220V±10%50HZ

Power:about 200W

Main material:SUS304

■ Main Features

1. Optimized for Bottled Products

Compared to ordinary checkweighers, clamp-type bottle checkweighers offer more stable performance with lightweight bottles, empty bottles, liquid bottles, and plastic bottles.

2. Higher Dynamic Weighing Accuracy

Effectively controls weighing drift caused by bottle movement, making dynamic accuracy closer to static weighing.

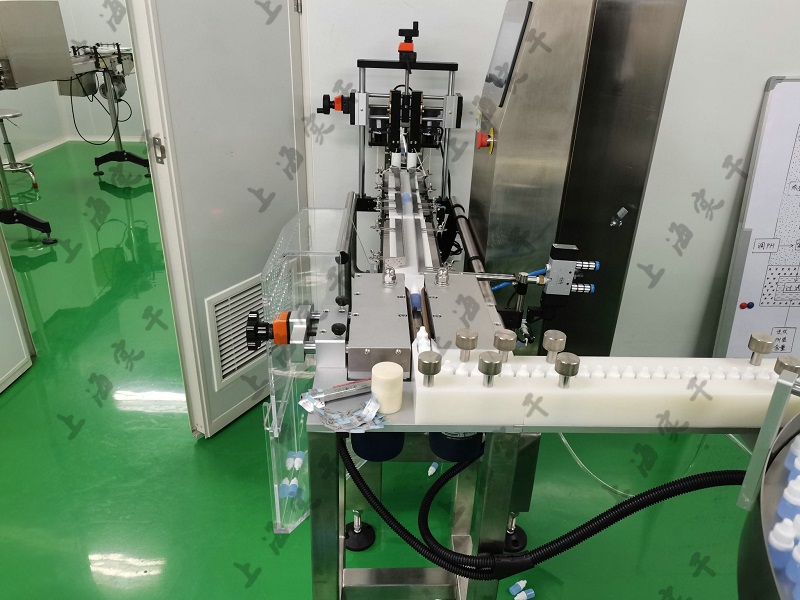

3. Easy Production Line Integration

Seamlessly compatible with filling machines, capping machines, labeling machines, and other equipment, enabling automatic weighing and error correction.

4. Intelligent Data Management

Supports production data statistics, weight trend analysis, USB export, Ethernet communication, and other functions.

Clamping Device Features

1. Stabilizes Bottle Posture

Clamps and secures lightweight or tall bottles.

Effectively prevents weighing fluctuations caused by tipping, bouncing, or swaying.

2. High-Speed Conveying Without Deviation

Ensuring bottles pass upright over the weighing platform on high-speed conveyors.

Achieves stable detection at 60–300 bpm (depending on bottle type and weight).

3. Wind and Shock Resistance

The clamping structure reduces interference from ambient airflow and conveyor vibrations.

Ensures high repeatability and reduces false positives.

4. Adaptable to Various Bottle Types

Adjustable clamping spacing and height.

Supports round, square, irregularly shaped, and transparent bottles.

5. No Bottle Damage

Uses food-grade or soft materials for bottle clamping.

Ensures a scratch-free and deformation-free appearance.

■ Application

■ Customers

■ Exhibitions

■ Packaging & Delivery

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.

Tags

CE Checkweigher for Capsule Production Line

2-Track Blister Stick Checkweigher

Multi lane Conveyor Checkweigher (10 Track)

Small Size Tablet Sampling Checkweighe

Metal Detector for Capsules Tablets APIs

Inline Production Combi Metal Detector and Checkweigher