|| Product Introduction

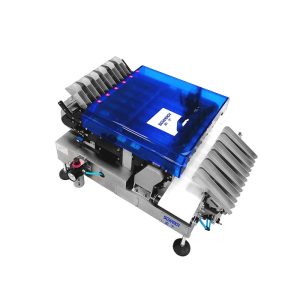

Sachet Stand-up Pouch Dynamic Checkweigher is a machine that verifies the weight of individual sachets on a production line.Checkweigher Systems for Food Production Line ensures that each sachet contains the correct amount of product, rejecting those that are under or overweight.This is crucial for maintaining product quality, meeting regulatory standards, and minimizing waste.

Sachet Checkweigher

|| Tech Specifications

Type:Customized

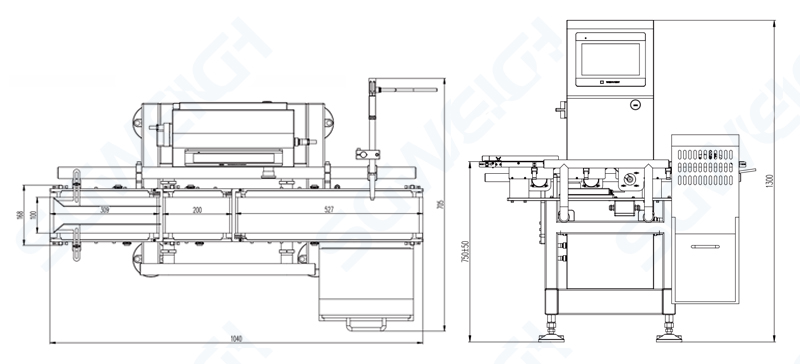

Weighing Range:2-300g

Limited of product:L:100 W:100 H:2-150mm

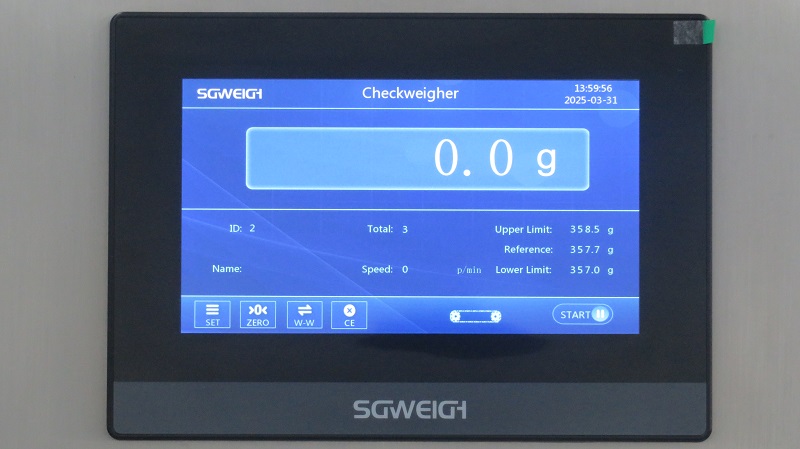

Accuracy:±0.05g Depend on products

Division Scale:0.01g

Belt Speed:0-90m/min

Max Speed:260 pcs/min

Belt Width:100mm

Machine Weight:70kg

Power Supply:AC 110/220V ±10% 50HZ

Power:100W

Main Material:SU304 stainless steel

|| Main Features

1.Quality Control: Ensures consistent product fill and prevents under or over-filled of sachets or pouch.

2.Cost Savings: Reduces product giveaway and waste by identifying and removing underweight products.

3.Regulatory Compliance: Helps meet weight regulations and standards.

4.Increased Efficiency: Automated weighing process streamlines production and reduces manual intervention.

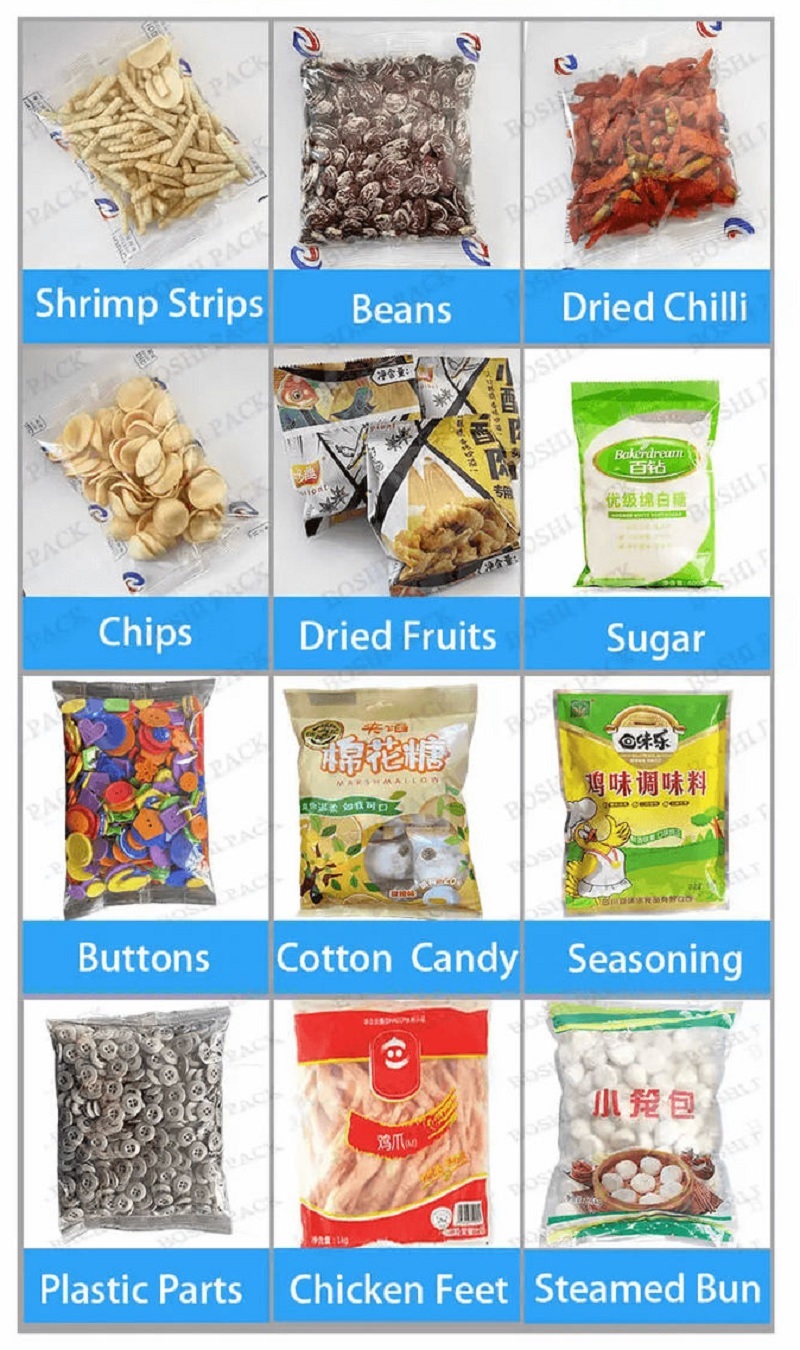

|| Application

|| Our Customers

|| Our Exhibitions

|| Package & Shipping

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.

TAGS:Food Checkweigher Industrial Checkweigher Pharmaceutical Checkweigher Food Metal Detector Pharmaceutical Metal Detector Check Weigher Metal Detector Combo