This is a fascinating and highly specific application of metal detection.Vertical Fall Metal Detector for Bulk Materials is a critical piece of equipment for ensuring product purity and protecting downstream machinery in industries processing dry, free-flowing powders.

A vertical fall metal detector is designed to inspect free-flowing bulk powders (e.g., flour, sugar, spices, milk powder, plastics, pharmaceuticals) as they gravity-feed through a pipeline or chute.

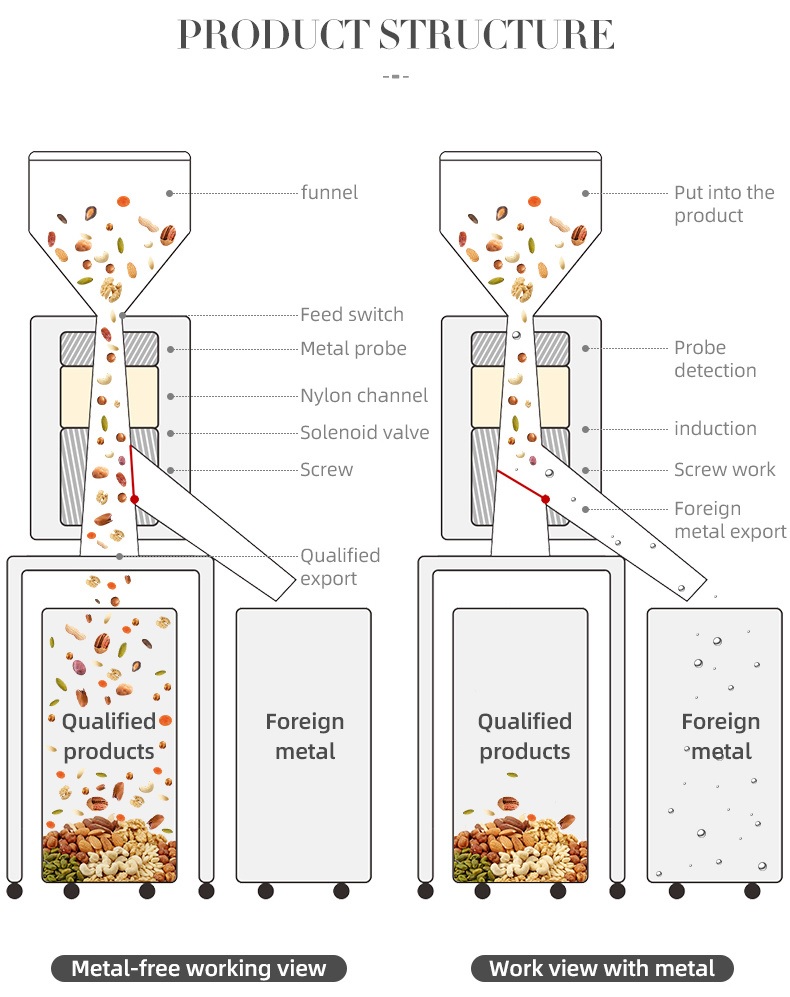

Basic Principle:

Product Flow: Powder is fed from a hopper or silo above the detector.

Free-Fall Chamber: The powder enters the top of the detector and falls vertically through an inspection aperture or “aperture tube,” typically made of food-grade plastic.

Detection: The aperture is surrounded by a balanced coil system (one transmitter coil and two receiver coils). The transmitter coil generates a high-frequency electromagnetic field.

Signal Disturbance: Any metallic contaminant (ferrous, non-ferrous, or stainless steel) passing through this field causes a detectable disturbance.

Rejection: Upon detection, the system sends a signal to a rejection mechanism (like a high-speed air blast or diverter valve) to remove the contaminated product from the flow stream.

A Vertical Fall Metal Detector is the optimal and most efficient solution for inspecting bulk powders. Its non-contact, gravity-fed design offers superior hygiene, high sensitivity, and seamless integration into processing lines, providing an essential critical control point for product safety and quality assurance.

TAGS

Bulk Materials Vertical Free Fall Metal Detector for Grains Granule