|| Product Introduction

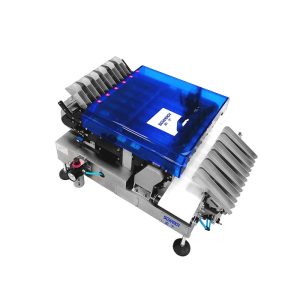

The Stand-up Pouch Fruit and Vegetable Puree Checkweigher is an online automatic weight detection device specifically designed for vertically packaged fruit and vegetable puree products. It is typically installed at the end of the packaging production line to accurately measure the weight of each bag of puree in real time, ensuring the product meets the set acceptable weight range.

This Checkweigher with Auto Reject System can adapt to liquid or semi-fluid products with high fluidity and variable weight (such as apple puree, banana puree, carrot puree, spinach puree, etc.), improving quality control efficiency and reducing human error.

|| Tech Specifications

Model:SG-150

Weighing range:5-500g

Minimum scale:0.1g

Checking speed :Max 120pcs/Min

Belt speed:0-65m/min

Box size limit:Length:200mm Width:150mm Height:3-200mm

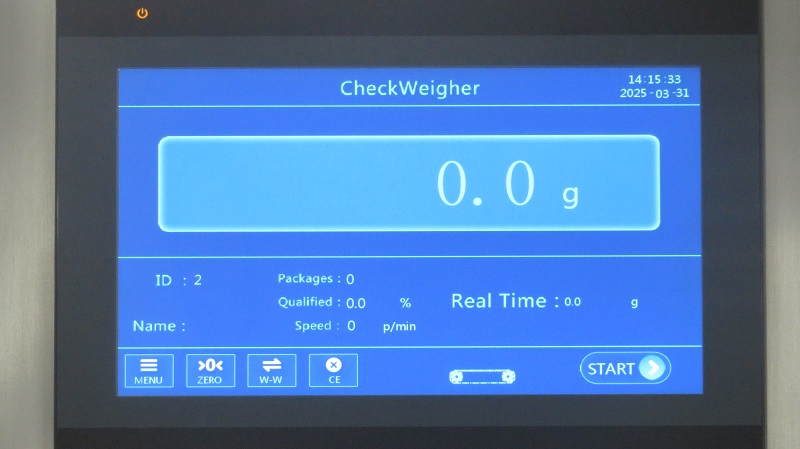

Operation Way:Touch operation

Conveying direction:Facing the touch screen from left to right

Rejection method:Push Rejection

Belt height from the ground:750±50mm(can be customized)

Machine material:Stainless steel(SUS304)

Power supply:220V50/60HZ

Power:About300W

Windshield:8mm Thick acrylic (to avoid airflow interference)

Feet M20 stainless steel with shock-absorbing rubber pad

External air source:0.2-0.6Mpa Air pressure port:Φ8mm

Working environment:Temperature:0℃~40℃,Humidity:30%~95%

Remark:The properties of the tested products and the use environment are different,and the detection speed and accuracy are also different.The actual test is used as the standard.

|| Main Features

1. High-Speed Automatic Weighing

● Employs high-speed, high-precision weighing sensors;

● Each bag is weighed independently during transport, eliminating the need for downtime;

● Suitable for high-volume production lines.

2. Adaptable to Vertical Bag Structure Design

● Dedicated support device prevents scale instability caused by the high fluidity of fruit and vegetable purees;

● Provides excellent measurement compensation for the weight of the vertical bag and changes in the center of gravity of the liquid;

● Auxiliary support frame can be adjusted according to bag width/height.

3. Automatic Rejection of Defective Products

● Linked with rejection devices (such as cylinder push rods, robotic arms, and diversion rails):

● Below the lower limit → Automatic rejection;

● Above the upper limit → Automatic rejection;

● Ensures that all products ultimately destined for subsequent packaging/boxing are of acceptable weight.

4. Intelligent Control and Parameter Setting

● Touchscreen interface for intuitive parameter settings;

● Settable:

● Target weight

● Upper/lower tolerance limits

● Segmented weight range sorting

● Automatic calibration cycle

● Data display includes pass rate, rejection rate, and production statistics.

5. Automatic Data Recording and Traceability

● Records weight data for each bag for traceability;

● Supports exporting to Excel/database interfaces, facilitating quality tracking and auditing;

● Integrates with MES/ERP systems to enhance production control capabilities.

6. Clean and Hygienic Design

● SUS304 stainless steel body;

● Waterproof rating IP65 or higher;

● Smooth structure for easy rinsing and residue prevention;

● Suitable for food-grade production environments such as fruit and vegetable puree production.

7. Compatibility and Expandable Functions

● Can be integrated with the following equipment:

● Vertical bag filling machine

● Vacuum packaging machine

● Sealing machine

● Automatic coding/inkjet printer

● Metal detector

|| Application

✔ Fruit puree, vegetable puree

✔ Fruit juice concentrate

✔ Infant food puree

✔ Functional beverage puree

✔ Sauces, seasoning puree

✔ Nutritional puree products

|| Customers

|| Exhibitions

|| Packaging & Delivery

● Our machines undergo comprehensive testing and commissioning before shipment to ensure stable and reliable performance.

● Equipment is packaged in thickened wooden crates with shock and moisture-proof interiors to effectively prevent damage during transportation.

● We partner with several professional international logistics companies and support a variety of shipping methods, including sea, air, and land transport.

● Ensure the equipment arrives safely and on time at your facility.

TAGS