Product Summarize

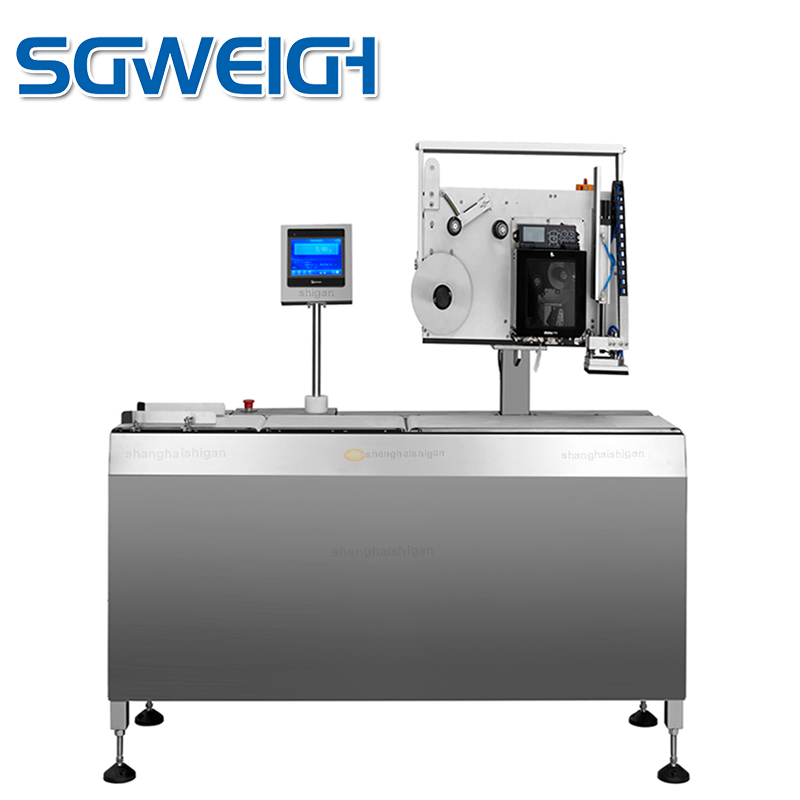

SG-T300 Automatic Weigh Labeler for Large Packaged Carton Pork / Beef, also known as a weigh labeling machine or a weigh-price labeling system, is a type of equipment used in various industries, including food, pharmaceuticals, and logistics, to weigh products and apply labels with accurate weight information.Welcome to consult for quotation information!

Product Parameter

Model: SG-T300

Weighing range: 5-3000g

Product restrictions: L: 350 W: 300 H: above 3mm

Sorting accuracy: ±0.3-0.5g (depend om products)

Sorting value: 0.1g

Belt speed: 0-30m/min

Maximum speed: 30pcs/min

Belt width: 300mm

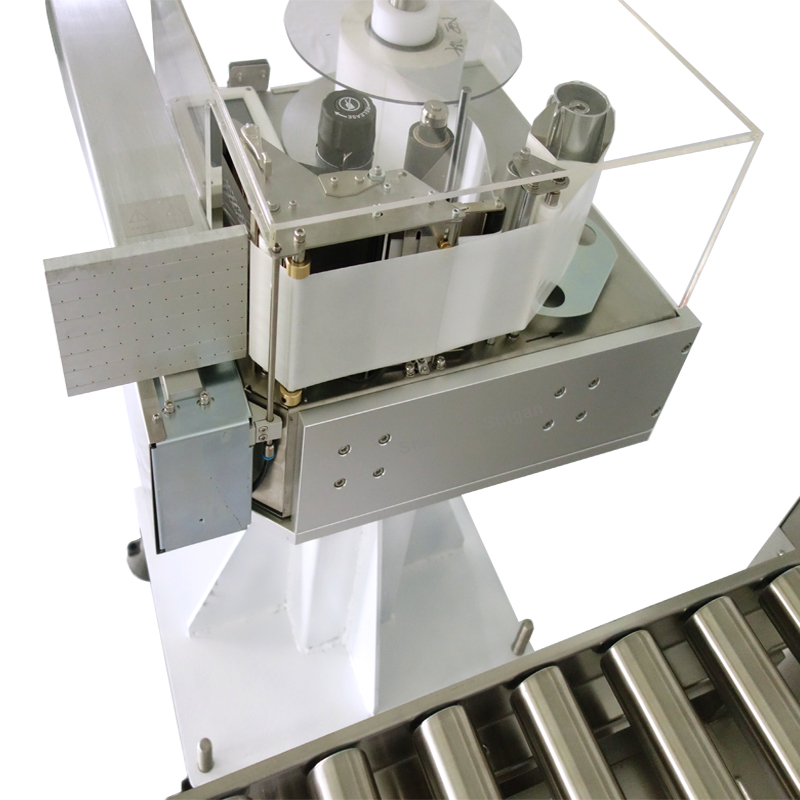

Printing method: Heat transfer printing or direct heating printing

Printing specifications: maximum printing width 104mm

Machine weight: 200kg

Power supply: AC 220V±10% 50HZ

Power: 300W

Main material: SUS304 stainless steel

Product Characteristics

1. Weighing System:

The machine is equipped with a precise weighing system that accurately measures the weight of individual products. This can involve the use of load cells or other technologies to ensure high accuracy.

2. Labeling Unit:

A labeling unit is integrated into the machine to apply labels containing weight information directly onto the products. This labeling process often occurs in real-time as products move through the machine.

3. Automatic Adjustment:

The machine may have automatic adjustment capabilities to accommodate variations in product size and weight. This is important for handling different types of products within a production line.

4. High-Speed Operation:

Many weight labeling machines are designed for high-speed operation to keep up with the pace of modern production lines. This is especially important in industries where large quantities of products need to be labeled quickly.

5. Touchscreen Interface:

A user-friendly touchscreen interface is often incorporated into the machine, allowing operators to easily set parameters, monitor the labeling process, and make adjustments as needed.

6. Versatility:

Weight labeling machines are often versatile and can handle a variety of packaging types, shapes, and sizes. They may be suitable for labeling individual items, trays, or packages.

Specific Application

Company Profile

Customer Visit

Exhibition

Packaging&Shipping

Hot Labels

Food Checkweigher

Pharmaceutical Checkweigher

Industrial Checkweigher

Check weight machine

Multi-level Sorting Checkweigher

Food Metal Detector

Pharmaceutical Metal Detector

Industrial Metal Detector

Checkweigher and Metal Detector Combo