■ Product Introduction

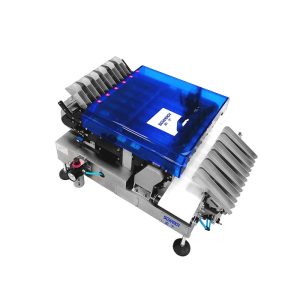

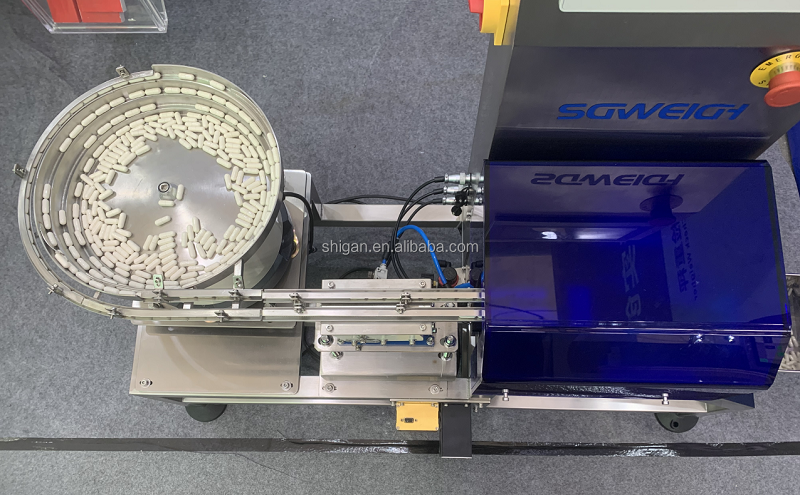

Pharmaceutical companies have introduced SG-DJ10 Automatic Sampling Checkweigher on their production lines to periodically inspect capsules or tablets. The motor drives the reclaimer to extract some medicines at regular intervals, and convey them into the buffer bin at the entrance of the Sampling Checkweigher through vibration, where they are automatically loaded, queued, and weighed one by one.

Checkweigher (mg) for Tablets & Capsules

■ Tech Specifications

Type: SG-DJ10

Weighing range: 20-2000mg

Sorting accuracy: ±1mg (Depends on products)

Graduation value: 0.1mg

Single lane speed: 100pcs/min

Power supply:AC220V±10%50HZ

Power:about 100W

Weight of machine:about 80kg

Main material:SUS304(Stainless Steel)

■ Main Features

1. High-Precision Weighing

■ High resolution and accuracy ensure detection of even the smallest weight discrepancies.

2. Weight Discrepancy Check

■ Preset Upper and Lower Limits: Operators can pre-set acceptable weight deviation ranges based on internal standards (e.g., ±5%, ±10%, or specific milligrams).

■Automatic judgment: The checkweigher automatically compares the weight of each sample with the preset limits and immediately displays the result (such as pass/fail, exceeded upper/lower limit).

■ Reject: Samples outside the pre-set range are automatically rejected.

3. User Management

■ Supports multiple user login levels (e.g., operator and administrator), with different permissions corresponding to different operating ranges.

■ Automatically records all weighing operations, including operator ID, product information, weighing data, calculation results, and timestamps.

4. Data Output and Storage

■ Built-in Storage: Capable of storing a large number of weighing results and product recipes.

■ Data Interface: Typically equipped with RS232, USB, or Ethernet interfaces, data can be directly transferred to a computer, printer, etc.

■ Application

■ Customers

■ Exhibitions

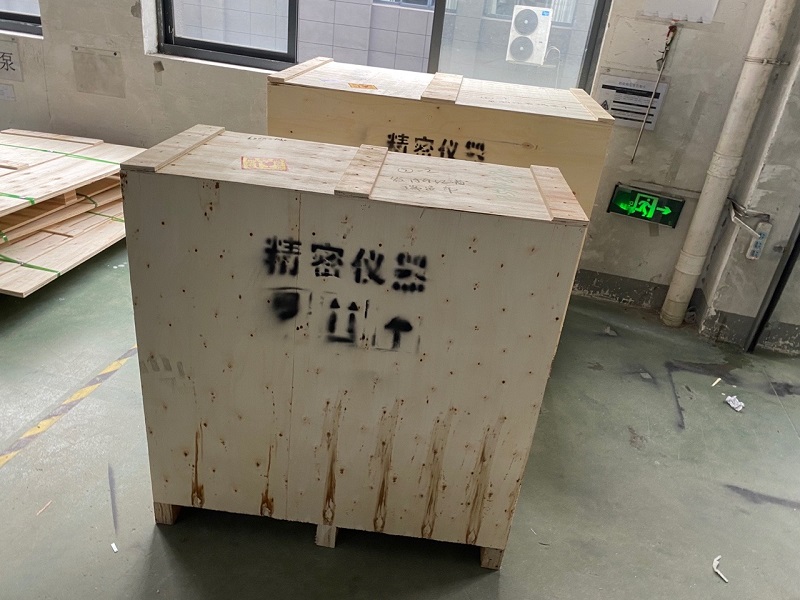

■ Package & Shipping

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.

TAGS

High-Speed 100% Capsule Checkweigher

Single-Dose Packet Multi-lane Checkweigher

Tablets Metal Detector Connected to Tablet Press

Food Safety Conveyor Metal Detector