Product Summarize

SG-220U Automatic Food Industrial Check Weigher is a machine used in the food packaging industry to ensure that the weight of individual bags of potato chips meets certain specifications. This is important for quality control.By employing Bagged Potato Chip Cashew Check Weigher, manufacturers can enhance the quality and consistency of their products while meeting regulatory requirements. It’s a critical component in the production process to ensure that consumers receive the correct weight of product in each package.Welcome to consult for quotation information!

Product Parameter

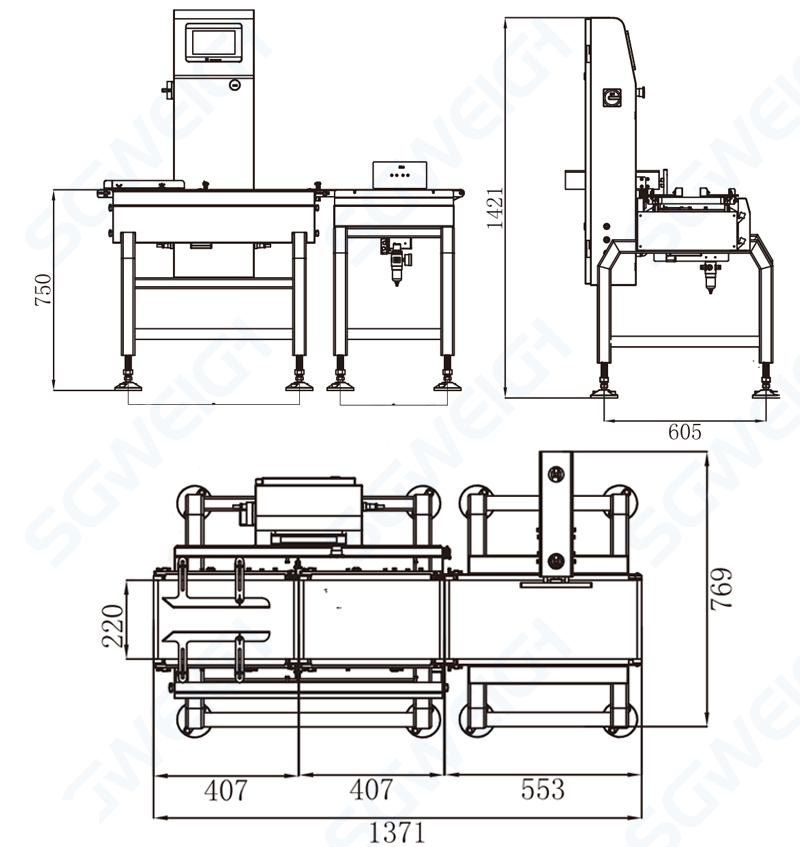

Type:SG-220U

Weighing Range:5-1500g

Limited of product:L: 300 W:220 H: 3-200mm

Accuracy:±0.2g Depends on product

Division Scale:0.1g

Belt Speed 0- 60m/min

Max Speed 100 pcs/min

Belt Width:220mm

Machine Weight:65kg

Power Supply:AC 220V 50HZ

Power:200W

Main Material:SUS304 stainless steel

Product Characteristics

1.Conveyor Belt:

The bags of potato chips are placed on a conveyor belt, which moves them along to the checkweigher.

2.Weighing Mechanism:

As each bag passes through the checkweigher, the machine uses a weighing mechanism to measure its weight.

3.Comparison with Set Standards:

The measured weight is then compared to a predefined target weight or weight range that is considered acceptable for that particular product.

4.Sorting or Rejecting:

If a bag is found to be outside the acceptable weight range, the checkweigher triggers a mechanism to either sort the bag for further inspection or reject it from the production line. This helps to ensure that only bags with the correct weight reach the consumer.

5.Data Logging:

Some advanced checkweighers are equipped with data logging capabilities, which record information about each bag’s weight.

6.Integration with Packaging Line:

Checkweighers are often integrated into the packaging line, working seamlessly with other equipment such as baggers and sealers. This automation helps maintain efficiency and accuracy in the packaging process.

Specific Application

Company Profile

Customer Visit

Exhibition

Packaging&Shipping

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

After Sale Service

1.Product quality commitment

(1).There are quality records and testing data for the manufacture and testing of products.

(2).For the inspection of product performance,we sincerely invite users to inspect the whole process and performance of the product in person.After the product is confirmed to be qualified,it will be packaged and shipped.

2.the product price commitment

Under the same competitive conditions, our company will sincerely provide you with a preferential price on the basis of not reducing the technical performance of the product or changing the product components.

3. Delivery time commitment

Product delivery time: as far as possible according to user requirements,if there are special requirements, it needs to be completed in advance,and strive to meet user needs.

Hot Labels

Food Checkweigher

Pharmaceutical Checkweigher

Industrial Checkweigher

Check weight machine

Multi-level Sorting Checkweigher

Food Metal Detector

Pharmaceutical Metal Detector

Industrial Metal Detector

Checkweigher and Metal Detector Combo