■ Product Introduction

Metal Detector and Checkweigher Combo is an integrated inspection system used primarily in food, pharmaceutical, and packaging industries to ensure product safety and compliance with weight regulations. This combination system performs two critical quality control functions simultaneously:

Metal Detection

Detects ferrous, non-ferrous, and stainless steel contaminants.

Ensures product safety by removing metal-contaminated items.

Sensitivity adjustable based on product type and packaging.

Checkweighing (Weight Inspection)

Verifies if products meet specified weight limits.

Helps prevent underfilling or overfilling, ensuring compliance with regulations.

Reduces giveaway (excess product) and improves cost efficiency.

■ Tech Specifications

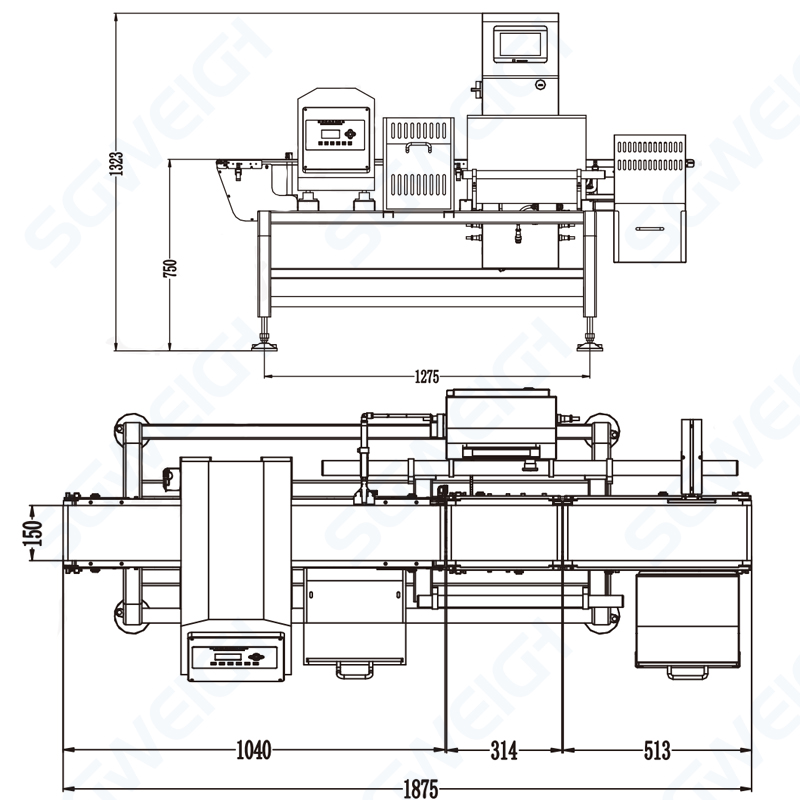

Model: SG-JS150

Detection hole width: 150mm

Detection hole height: 100-200mm

Detection sensitivity:

H-100mm: Fe≥Φ0.8mm,SUS≥Φ1.2mm

H-120mm: Fe≥Φ0.8mm,SUS≥Φ1.8mm

H-150mm: Fe≥Φ1.2mm,SUS≥Φ2.0mm

H-200mm: Fe≥Φ1.5mm,SUS≥Φ2.5mm

Weighing range: 5-500g

Weighing accuracy: ±0.1g(Depends on products)

Conveyor belt height: 750mm (±50mm)

Conveying capacity: 10Kg/time

Delivery direction: from left to right

Maximum speed of conveyor belt: 25m/min

Conveyor belt material: food grade PU belt

Protection class: IP65

Display and operation mode: LED LCD flat button input

Machine weight: 240kg

Power requirements: AC220V 50HZ

Power: 300W

■ Main Features

1. Dual Functionality:

Simultaneously checks product weight and detects metal contaminants, optimizing space and efficiency.

2. Compact Design:

By combining two machines into one, it saves production floor space and is suitable for facilities with limited space.

3. High Precision and Accuracy:

Advanced load cells and detection coils ensure accurate weight readings and highly sensitive metal detection.

4. Customizable Rejection Mechanism:

Optimizes options for pneumatic pushers, flippers, or pull-down mechanisms to automatically remove non-compliant products.

5. User-Friendly Interface:

A touchscreen interface allows for easy setup, calibration, and monitoring of weight and contamination parameters.

■ Application

■ Company

■ Customers

■ Exhibitions

■ Package & Shipping

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.

TAGS:

Capsule Checkweigher

Multi-Lane Check Weigher

Pharmaceutical Checkweigher

Capsule Tablet Metal Detector