■ Product Introduction

Online Bottle and Can Weight Checker is an essential quality control device used in production lines to ensure that products like bottles and cans meet specified weight requirements. Checkweigher for Beverage Industry helps in detecting underweight or overweight items, ensuring compliance with regulations, reducing waste, and maintaining customer satisfaction.

■ Tech Specifications

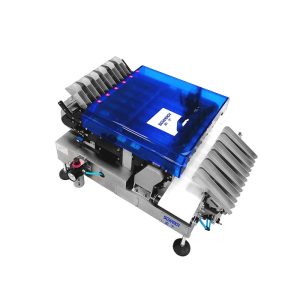

Type:SG-150U

Weighing Range:3-500g

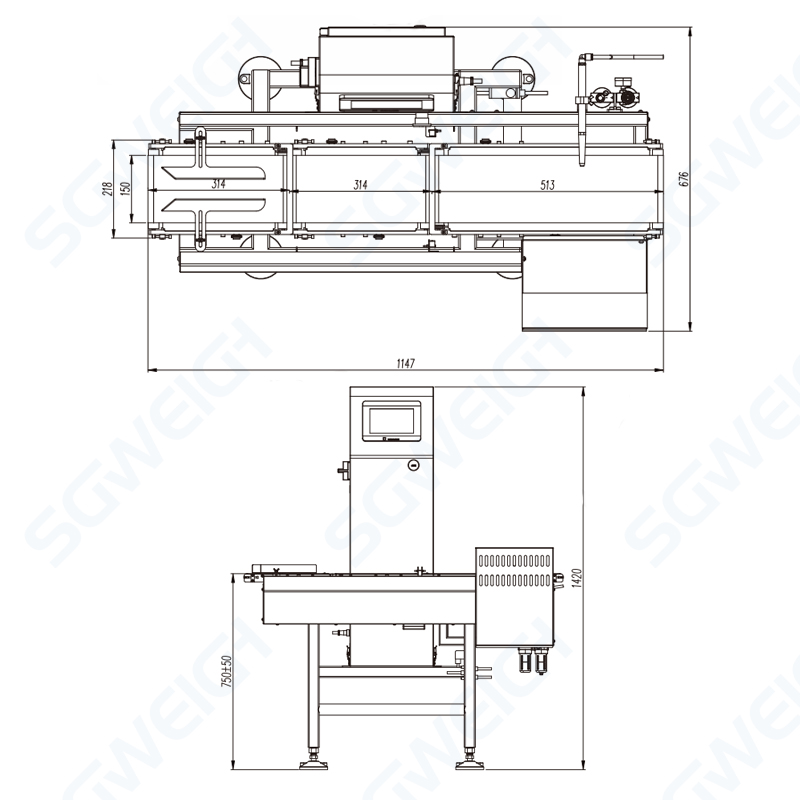

Limited of product:L: 200 W:150 H: 3-200mm

Accuracy:±0.1g Depends on product

Division Scale:0.1g

Belt Speed:0- 60m/min

Max Speed:150 pcs/min

Belt Width:150mm

Machine Weight:60kg

Power Supply:AC 110/220V±10% 50HZ

Power:100W

Main Material:SUS304 stainless steel

■ Main Features

1.High-Speed Weighing

Designed for fast-moving production lines (e.g., food, beverages, pharmaceuticals).

Can handle hundreds of items per minute.

2.Accuracy & Precision

Measures weight deviations (e.g., ±0.1g to ±2g, depending on product requirements).

Rejects underfilled/overfilled containers automatically.

3.Integration with Production Lines

Works seamlessly with filling, capping, and labeling machines.

Can be linked to PLCs or SCADA systems for data logging.

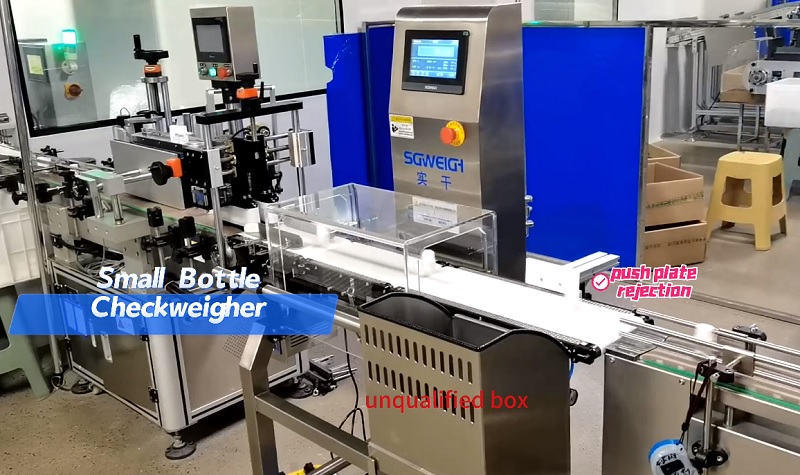

4.Rejection System

Uses air jets, pushers, or conveyor diverters to remove non-compliant products.

5.User-Friendly Interface

Touchscreen controls for easy setup and monitoring.

Stores weight data for traceability and reporting.

6.Hygienic Design (for Food/Beverage Use)

Stainless steel or food-grade materials for easy cleaning.

IP-rated for dust/water resistance.

7.Multi-Lane Capability (for High-Volume Lines)

Some models can weigh multiple bottles/cans simultaneously.

■ Application

✔ Beverage Industry – Checks filled bottles (water, soda, beer) and cans.

✔ Food Industry – Ensures correct fill levels in jars, pouches, and cans.

✔ Pharmaceuticals – Verifies dosage accuracy in liquid medicine bottles.

✔ Cosmetics & Chemicals – Controls fill levels in lotions, sprays, and cleaners.

■ Customers

■ Exhibitions

■ Package & Shipping

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.

TAGS:

Capsule Checkweigher

Multi-Lane Check Weigher

Pharmaceutical Checkweigher

Capsule Tablet Metal Detector