■ Product Overview

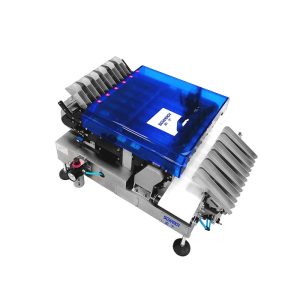

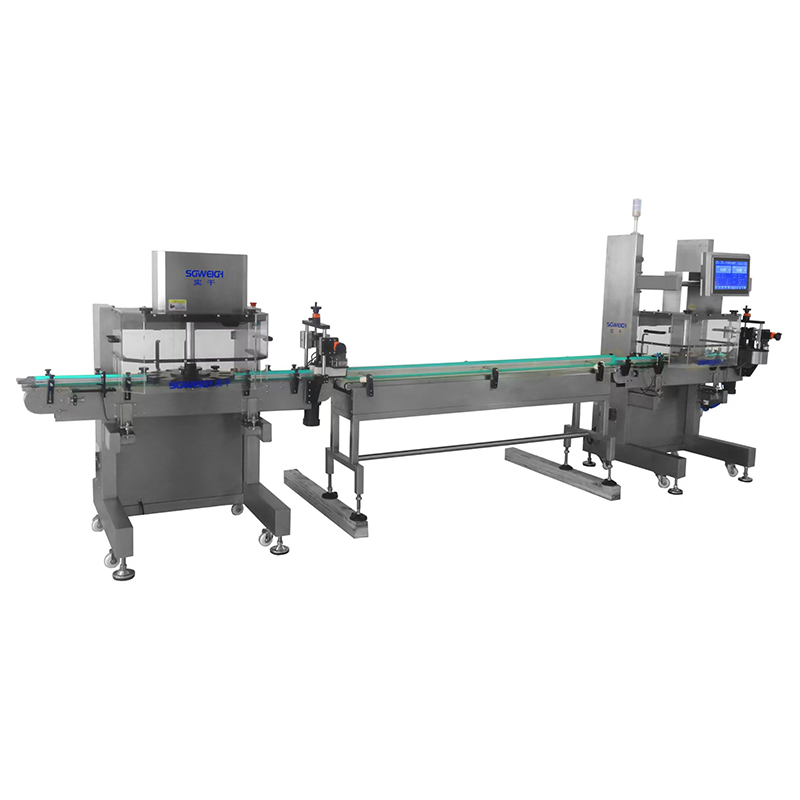

Rotary Bottle Checkweigher is a high-speed, continuous-motion weighing system designed specifically for round bottles, PET bottles, glass bottles, beverage containers, and pharmaceutical liquid bottles.

This Cans Production Line Weighing System integrates a rotary star wheel, precision load cells, and intelligent weight-analysis algorithms to ensure every bottle meets the defined weight tolerance. It supports full-bottle, half-bottle, and micro-dose liquid products with excellent accuracy and throughput.

■ Tech Specifications

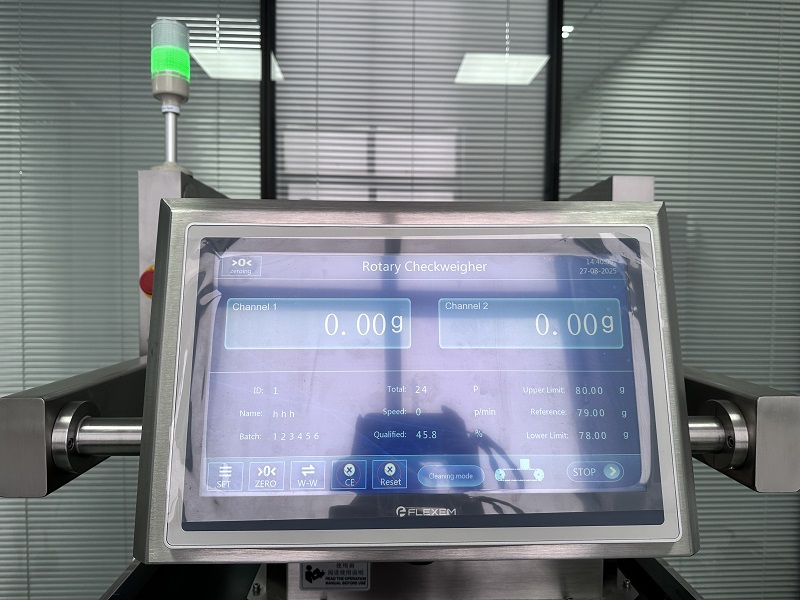

Model: SG-Z2 (dual channel)

Weighing range: 5-300g

Minimum scale: 0.01g

Sorting accuracy: ±0.02 grams (depending on the product)

Sorting speed: maximum 50 pieces/minute (single channel)

Conveying speed:0-50m/min

Operation mode: touch operation

Conveying direction: Facing the touch screen from left to right

Rejection method: air blowing removal/push plate removal

Belt height from the ground: 750±50mm (can be customized according to customer requirements)

Machine structure: stainless steel (SUS304)

Power supply: 220V 50-60HZ

Power: about 1500W

Windshield: thick acrylic (to avoid airflow interference)

■ Main Features

1. Continuous High-Speed Weighing

Rotary star-wheel design ensures stable bottle transfer at speeds up to 60.120.180 bottles/min.

2. Intelligent Bottle Handling

360° bottle guidance for PET, HDPE, and glass bottles.

Anti-tilt mechanism ensures stable weighing even for lightweight thin-wall bottles.

3. Automatic Reject & Sorting System

High-speed pneumatic, pusher rejection.

Supports underweight, overweight, missing-liquid, and cap missing detection.

4. Hygienic & Durable Structure

Full stainless-steel design, IP65 protection

Tool-free changeover for different bottle sizes

5. Data Connectivity & Traceability

7–15 inch touchscreen HMI

Multi-level password management

USB export, Ethernet, OPC UA, and connection to MES/SCADA

Real-time SPC statistics and trend analysis

■ Application

■ Customers

■ Exhibitions

■ Packaging & Delivery

Our machines is fully tested and calibrated before delivery.

It is packed in a strong wooden case with internal shockproof protection.

Various shipping options are available — by sea, air, or land — ensuring safe and on-time delivery by professional logistics partners.

TAGS