■ Product Overview

The Inline Dual-lane Checkweigher is designed for simultaneous weight inspection of two product lanes, significantly increasing throughput while maintaining high accuracy. It is ideal for high-speed packaging lines handling small to medium-sized items such as sachets, sticks, pouches, cartons, and wrapped products.

By weighing two lanes independently within a single system, the Multiple-Lane Conveyor Weighing System helps manufacturers save floor space, reduce equipment costs, and improve production efficiency, while ensuring every product meets strict weight requirements.

■ Tech Specifications

Model: SG-2X

Weighing range:1 to 500g

Graduation value: 0.01g

Throughput:40-60 products/min (per lane)

Accuracy (3σ) : +/- 0.2g(Depends on products)

Display :8.5-inch

Operation method:Touch panel

Preset memory:Up to 100

Product size :

Width 10 to 160 mm

Length 10 to 200 mm

Height 5 to 200 mm

Exterior:Stainless steel (SUS304)

■ Main Features

1.Two Independent Weighing Lanes

Each lane operates with its own load cell and control logic, ensuring accurate and stable weight inspection for both product flows.

2.High Throughput, Space-Saving Design

One dual-lane checkweigher replaces two single-lane units, ideal for compact production environments.

3.High Accuracy & Stability

Advanced digital load cell technology delivers precise weighing even at high conveyor speeds.

4.Automatic Weight Rejection

Underweight and overweight products are automatically rejected using pneumatic or mechanical rejection systems.

5.User-Friendly Touch Screen Interface

Intuitive HMI for quick product setup, parameter adjustment, and real-time monitoring.

6.Easy Integration

Compatible with upstream filling machines and downstream metal detectors, labeling machines, or packing systems.

■ Application

■ Customers

■ Exhibitions

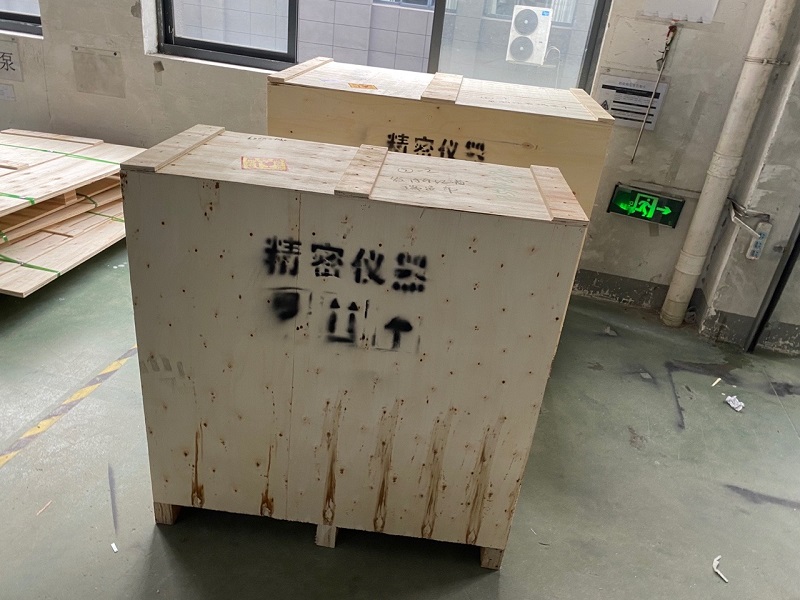

■ Packaging & Delivery

Our machines is fully tested and calibrated before delivery.

It is packed in a strong wooden case with internal shockproof protection.

Various shipping options are available — by sea, air, or land — ensuring safe and on-time delivery by professional logistics partners.

TAGS