With the diversification of automated production lines and the increasing complexity of spatial layouts, traditional horizontal conveyor checkweighing solutions are no longer sufficient to meet all production needs. For applications with height differences, limited space, or specific conveying angles, our company introduces the new generation Inclined Conveyor Checkweigher. With its innovative structural design and high-precision dynamic weighing technology, it provides enterprises with a more flexible and efficient online weight detection solution.

Product Overview

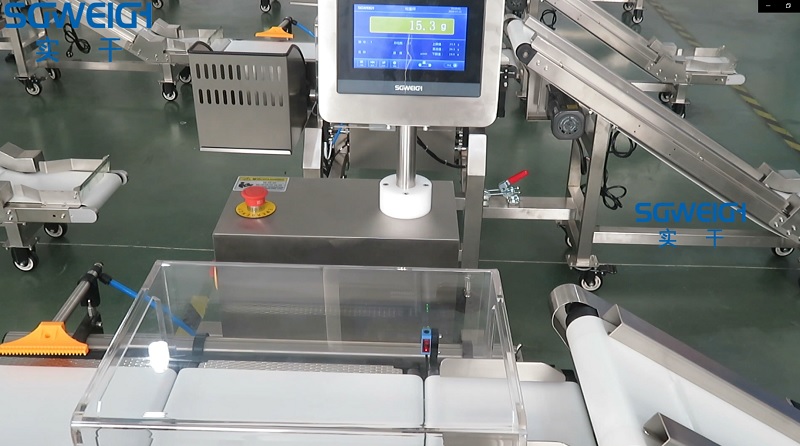

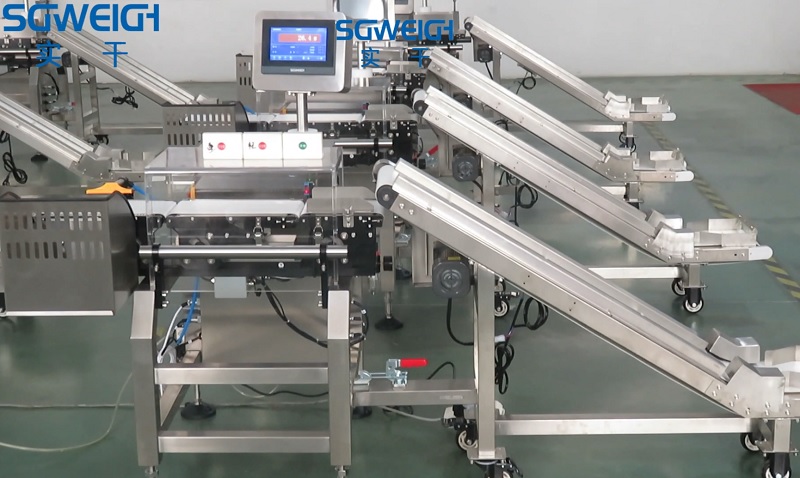

The Inclined Conveyor Checkweigher adopts an inclined conveyor structure, which can flexibly adjust the conveying angle according to the production line requirements. It is suitable for various product forms such as bagged, bottled, and boxed products, and is especially suitable for vertical transfer, lifting conveying, or production environments with limited space. This equipment can automatically weigh and sort products during continuous conveying, ensuring that the weight of each product meets the set standards.

Key Features

Precise Detection: Employing a high-sensitivity weighing module and a high-speed sampling system, the dynamic weighing accuracy can reach ±0.1g (depending on the product).

Inclined Design:Customizable conveyor angle perfectly adapts to production line layouts of varying heights and angles.

Stable Conveying:Dedicated anti-slip belt design ensures smooth operation during inclined conveying, unaffected by vibration.

Intelligent Rejection System:Configurable with various rejection methods such as push rods, air blowing, and swing arms for rapid sorting of defective products.

Easy-to-Clean Structure:Constructed entirely of stainless steel, with high waterproof and dustproof ratings, meeting GMP standards for the food and pharmaceutical industries.

Data Traceability:Equipped with a touchscreen interface and multiple communication interfaces, enabling data storage, statistics, and network management of weight data.

Application

The Inclined Conveyor Checkweigher is widely used in the food, pharmaceutical, daily chemical, agricultural, seafood, and packaging industries, and is particularly suitable for:

Inclined loading or unloading conveying applications

Corner areas of automated production lines

Space-constrained inspection stations

Conclusion

The introduction of the inclined conveyor checkweigher further expands the application boundaries of checkweighing equipment in complex production environments. It not only improves testing efficiency and accuracy, but also brings greater scalability and compatibility to automated production lines through its flexible structural design.

In the future, our company will continue to deepen its expertise in the online testing field, providing customers with more intelligent and customized weighing and testing solutions.

TAGS