■ Product Introduction

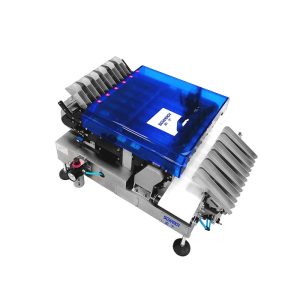

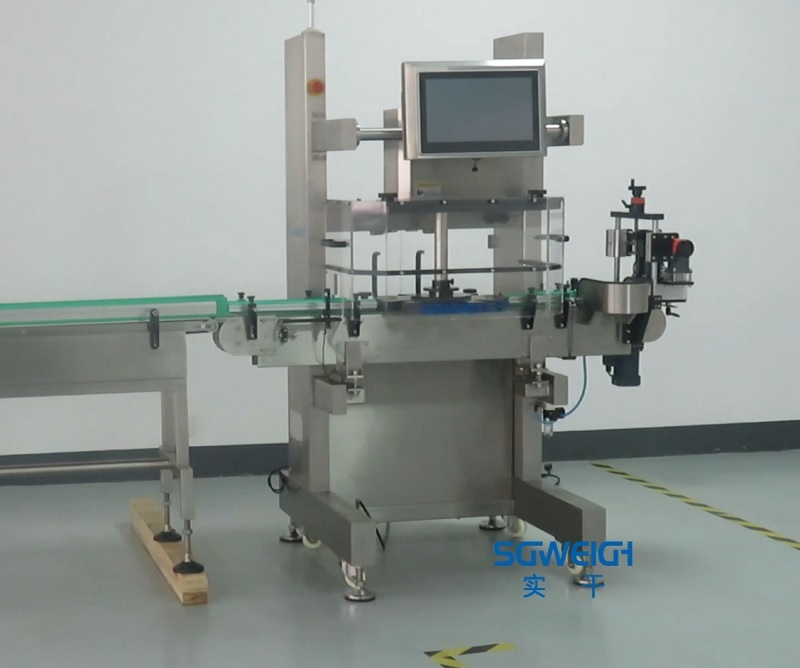

The High Speed Rotary Checkweigher can measure cylindrical products such as sprays, glass and plastic bottles, especially aerosol packaging, at high speed and can be easily integrated into the production line. The servo motor-controlled star wheel can be changed in a very short time to accurately weigh different products of different sizes.Weighing 2 bottles at the same time improves production efficiency.

Checkweigher with Feeding Belts – Bottles,Sprays,Cylindrical Products

Customized Rotary Checkweigher

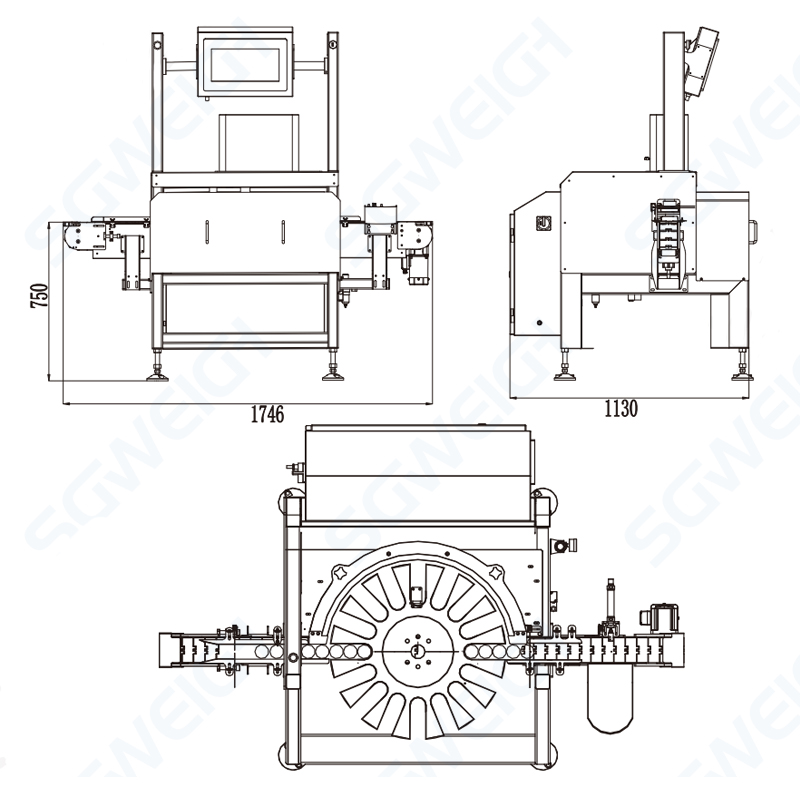

■ Tech Specifications

Model: SG-Z2 (dual channel)

Weighing range: 5-300g

Minimum scale: 0.01g

Sorting accuracy: ±0.02 grams (depending on the product)

Sorting speed: maximum 50 pieces/minute (single channel)

Conveying speed:20-50m/min

Operation mode: touch operation

Conveying direction: Facing the touch screen from left to right

Rejection method: air blowing removal/push plate removal

Belt height from the ground: 750±50mm (can be customized according to customer requirements)

Machine structure: stainless steel (SUS304)

Power supply: 220V 50-60HZ

Power: about 1500W

Windshield: thick acrylic (to avoid airflow interference)

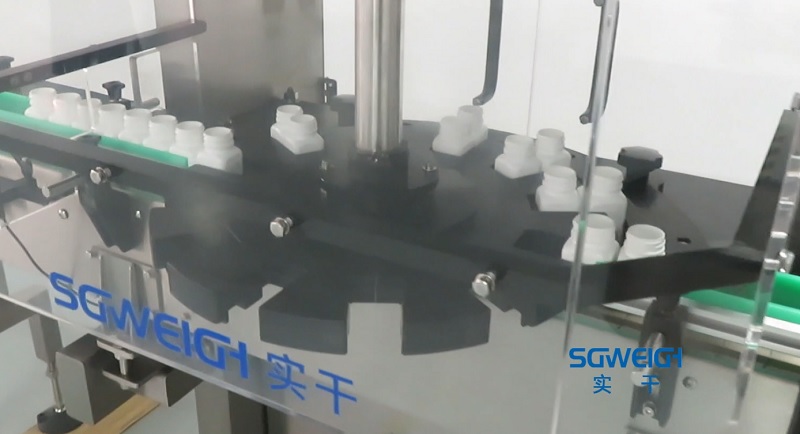

1.Bottles enter the conveyor belt

2.Bottles enter the turntable conveyor area, conveying 2 bottles at the same time

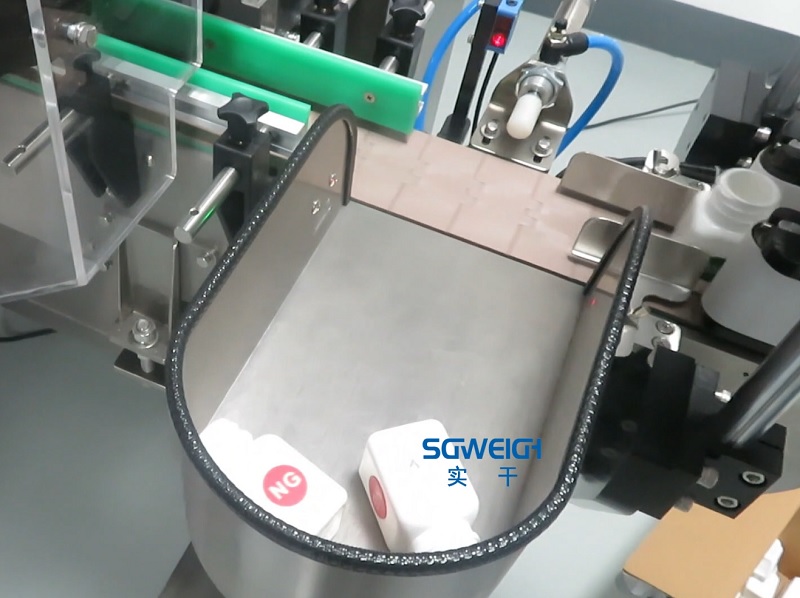

3.Enters the weighing area, and unqualified bottles are removed

4.Qualified bottles are conveyed to the next process

■ Main Features

◎Large screen display, clear viewing, easy operation.

◎Default Chinese and English operation interface.

◎Photoelectric positioning, turntable accurately sends products to the weighing sensor.

◎Chain conveyor is strong and durable.

◎Three-level operation authority management, support for self-set passwords.

◎100 product formulas are preset and stored.

◎Unqualified products are automatically rejected.

◎Multi-channel passing products to improve production efficiency (customizable number of channels).

■ Application

■ Customers

■ Exhibitions

■ Package & Shipping

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.

TAGS:Bottle Checkweigher for Pharma,Glass Bottle Check Weigher,Check Weighers | High Speed Checkweigher