■ Product Introduction

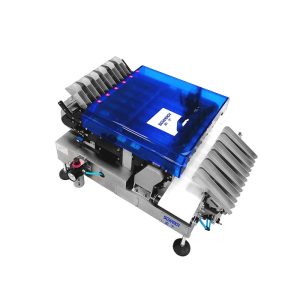

The Conveyor Food Metal Detector is a high-precision device used to automatically detect metallic foreign bodies in food production lines.High Precision Metal Detector is widely used in industries such as meat, aquatic products, baking, snack foods, dairy products, and condiments. Using highly sensitive electromagnetic induction technology, the device effectively detects metallic impurities such as ferrous, non-ferrous, and stainless steel, ensuring product safety and quality that meets food safety standards.

■ Tech Specifications

Type:SG-M400

Detection sensitivity: in empty state

H-100mm: Fe≥Φ0.8mm, Non-Fe≥Φ1.5mm, SUS≥Φ1.5mm

H-120mm: Fe≥Φ0.8mm, Non-Fe≥Φ1.5mm, SUS≥Φ2.0mm

H-150mm: Fe≥Φ1.0mm, Non-Fe≥Φ1.5mm, SUS≥Φ2.0mm

H-200mm: Fe≥Φ1.2mm, Non-Fe≥Φ2.0mm, SUS≥Φ2.5mm

Effective detection hole width: 150-1000mm customized according to requirements

Effective detection hole height: 80-500mm customized according to requirements

Maximum speed of conveyor belt: 25m/min

Conveyor belt material: food grade PU belt

Protection class: IP65

Display and operation mode: LED fast key input/Touch Screen Display

Machine weight: about 120kg

Power requirements: AC220V 50HZ

Power: 200W

Alarm mode: metal detection, alarm belt stop or automatic removal

■ Main Features

1.Metal Contaminant Detection

Detects and identifies all types of metal contaminants, including ferrous, non-ferrous, and stainless steel, ensuring product purity and consumer safety.

2.Automatic Rejection System

When metal is detected, the system automatically removes the contaminated product through various reject mechanisms such as air blast, flipper, or belt stop, preventing defective goods from continuing down the line.

3.High Sensitivity & Stability

Utilizes advanced digital signal processing (DSP) and multi-frequency technology to achieve high detection sensitivity while minimizing product effect interference, even in wet or salty food products.

4.User-Friendly Touchscreen Interface

Features an intuitive touchscreen control panel for easy operation, quick parameter setup, and system monitoring.

5.Data Recording & Traceability

Automatically records detection results, rejection events, and operational history, supporting traceability and compliance with HACCP, BRC, and IFS standards.

6.Hygienic & Durable Design

Constructed from stainless steel with smooth surfaces and IP65 waterproof rating for easy cleaning and maintenance in food production environments.

7.Integration with Production Line

Designed for seamless integration with existing conveyor systems, packaging machines, and checkweighers to create a fully automated quality control solution.

8.Auto-Learning Function

The system can automatically learn product characteristics and optimize detection settings to maintain stable performance across different products.

■ Application

■ Customers

■ Exhibitions

■ Packaging & Delivery

● Our machines undergo comprehensive testing and commissioning before shipment to ensure stable and reliable performance.

● Equipment is packaged in thickened wooden crates with shock and moisture-proof interiors to effectively prevent damage during transportation.

● We partner with several professional international logistics companies and support a variety of shipping methods, including sea, air, and land transport.

● Ensure the equipment arrives safely and on time at your facility.

TAGS

Pharmaceutical Metal Detection Systems

High Quality Food Grade Belt Metal Detector / Checkweigher

Bulk Materials Vertical Free Fall Metal Detector

Multi lane Conveyor Checkweigher (10 Track)

Full Automatic Capsule Tablet 20 lane Checkweigher

Small Size Tablet Sampling Checkweigher