■ Product Overview

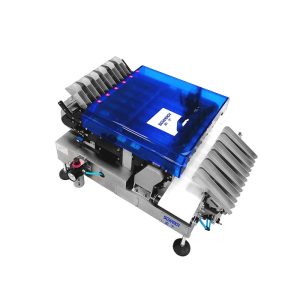

Food-Grade Conveyor Metal Detectors are highly sensitive devices integrated into continuous production lines for the automated, non-destructive detection of metallic foreign objects mixed into bulk or packaged foods.

Metal Detector can be seamlessly integrated into existing food production lines, achieving 100% online detection and effectively reducing food safety risks.

■ Tech Specifications

Type:SG-M400

Machine Grade:Food Grade

Detect method:Electromagnetic wave detection

Detecting width:150-1000mm customized according to requirements

Detecting height:80-500mm (or custom-made)

Detecting sensitivity:Fe 0.8mm, Non-Fe1.5mm, SUS 1.5mm

Detecting adjustment:Intelligent adjustable

Belt Speed:25m /min (or specified)

Alarm mode:The buzzer alarm, the motor automatically stop

Power:AC220V,50/60Hz (Or Customized)

■ Main Features

1. Food-grade structural design: The entire machine is constructed of food-grade stainless steel (typically SUS304/SUS316), meeting food safety regulations.

2. High-sensitivity detection technology: Digital signal processing (DSP) and multi-frequency detection technology ensure stable identification of minute metallic foreign objects.

3. Stable conveyor system: Food-grade belt conveyor, suitable for wet, dry, bulk, and individually packaged products.

4. Automatic rejection device: Supports multiple rejection methods including push-bar, flip-plate, air-blowing, and swing-arm types, ensuring accurate rejection of defective products.

5. Strong anti-interference capability: Features automatic product effect compensation for foods with high moisture content, high salt content, or large temperature variations.

6. Easy cleaning and maintenance: Open frame design supports quick disassembly and assembly, facilitating daily cleaning and disinfection.

■ Application

Meat products, seafood, and frozen foods.

Baked goods, confectionery, and snacks.

Convenience foods, seasonings, grains, and agricultural products.

Bagged, boxed, bulk, and direct-from-line products.

■ Customers

■ Exhibitions

■ Packaging & Delivery

● Our machines undergo comprehensive testing and commissioning before shipment to ensure stable and reliable performance.

● Equipment is packaged in thickened wooden crates with shock and moisture-proof interiors to effectively prevent damage during transportation.

● We partner with several professional international logistics companies and support a variety of shipping methods, including sea, air, and land transport.

● Ensure the equipment arrives safely and on time at your facility.

TAGS