■ Product Introduction

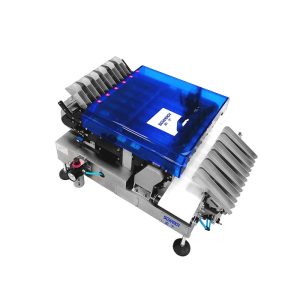

Our Explosion-Proof Custom Checkweigher is a high-precision, in-line dynamic weighing device designed for hazardous environments. Its explosion-proof design allows safe operation in production areas exposed to flammable dust or gas.End-of-Line Check Weigher is customizable and suitable for weighing, checking, and rejecting systems on various production lines.

■ Tech Specifications

Weighing range: 10g – 10kg (customizable)

Detection accuracy: ±0.1g to ±1g

Processing speed: 30–120 pieces/minute

Belt width: 100mm – 500mm (customizable)

Power supply: AC 220V / 50Hz

Explosion-proof rating: Ex d IIB T4 Gb (or customizable)

Rejection method: Air blow / push rod / flap / drop-down

Material: SUS304 stainless steel explosion-proof construction

■ Main Features

1. Explosion-proof design for safety and reliability

Equipped with an explosion-proof motor, explosion-proof load cell, and explosion-proof electrical control box.

Supports pneumatic rejection, explosion-proof solenoid valves, and air circuit systems.

2. High-precision dynamic weighing

Accuracy reaches ±0.1g, and speeds reach up to 120 pieces/minute (depending on the material).

Supports various rejection methods: push rod, air blow, flap, and drop-down.

3. Customizable design

Can be customized to meet the customer’s production line width, speed, and explosion-proof rating.

Supports integration with metal detectors and explosion-proof packaging lines.

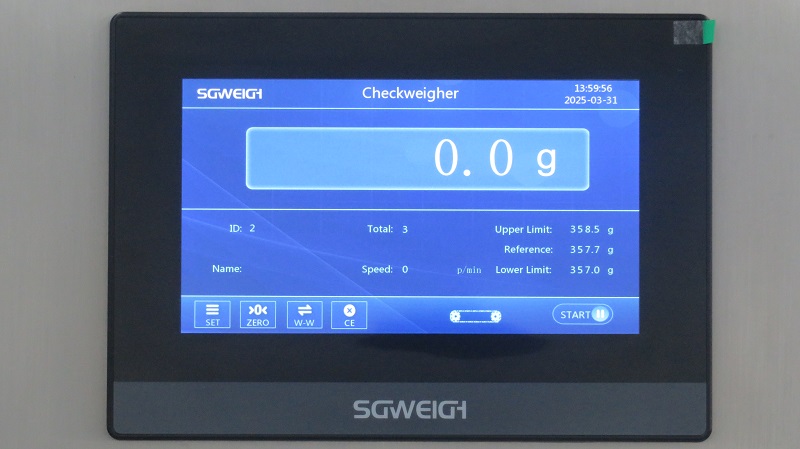

4. User-friendly interface

7-10 inch explosion-proof touchscreen operation for clear display and easy operation.

Multi-language interface available (Chinese, English, etc.).

5. Data traceability and networking

Supports USB export or Ethernet/Modbus communication for easy integration with MES systems.

Automatically records inspection data for production quality tracking.

■ Application

Chemical industry (powders, additives, pigments, coatings)

Pharmaceutical industry (APIs, powder packaging)

Food industry (flour, powdered sugar, seasoning powder)

Battery, coating, hazardous goods packaging

■ Customers

■ Exhibitions

■ Packaging & Delivery

● Our machines undergo comprehensive testing and commissioning before shipment to ensure stable and reliable performance.

● Equipment is packaged in thickened wooden crates with shock and moisture-proof interiors to effectively prevent damage during transportation.

● We partner with several professional international logistics companies and support a variety of shipping methods, including sea, air, and land transport.

● Ensure the equipment arrives safely and on time at your facility.

TAGS