■ Product Overview

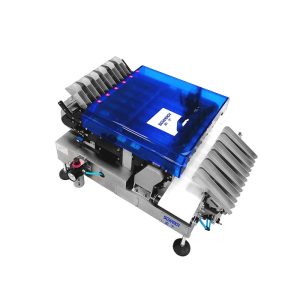

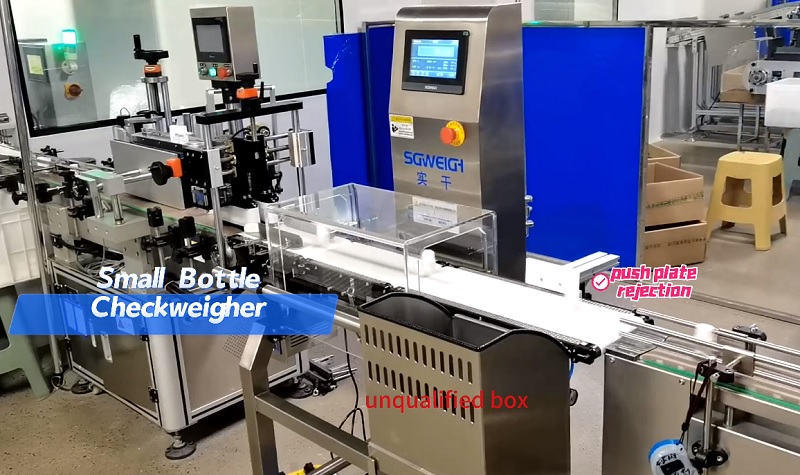

This Bottle Online Check Weigher System is an intelligent dynamic weight detection and sorting equipment specially designed for bottled product production lines. Adopting high-precision weighing sensors and advanced dynamic weighing algorithms,Bottle Weight Inspection Machine realizes real-time net weight inspection, over-weight/under-weight rejection and missing bottle detection for various glass, plastic and metal bottled products in food & beverage, pharmaceutical, cosmetic, chemical and agrochemical industries.

■ Tech Specifications

Type:SG-100HH

Weighing scope:2-300g

Restriction of product:L:100 W:100 H:2-150(mm)

Accuracy:±0.01g(Depends on products)

Division scale:0.01g

Highest speed:450pcs/min(Depends on products)

Belt width:100mm

Belt Speed:0-120m/min

Weight of machine:about 120kg

Power supply:AC220V±10%50HZ

Power:about 200W

Main material:SUS304

■ Main Features

1.High-Precision Dynamic Weighing

Adopts high-sensitivity digital weighing sensors and anti-interference dynamic algorithms, with weighing accuracy up to ±0.1g, ensuring stable and accurate weight detection for high-speed bottled production lines.

2.Multi-Type Defect Rejection System

Automatically identifies over-weight, under-weight, unqualified filling volume and missing bottle defects, equipped with optional air blast, push rod or flap rejection mechanisms to separate unqualified products without line stop.

3.Wide Compatibility for Bottle Varieties

Suitable for round, square, special-shaped plastic bottles, glass bottles, PET bottles and metal cans, compatible with empty bottle pre-inspection and filled bottle post-inspection working conditions.

4.High-Speed Production Line Adaptation

Supports adjustable running speed and multi-lane parallel design, matching high-output bottled filling lines to improve overall production efficiency without weighing performance loss.

5.Hygienic & Durable Structural Design

Built with 304/316 stainless steel fuselage, IP65 waterproof and corrosion-resistant grade, easy to clean and maintain, complying with food and pharmaceutical industry hygiene standards.

6.Intelligent Data Management & Traceability

Built-in data statistics module records qualified rate, total detection quantity and defect types; supports data export, USB/network transmission and production quality traceability.

7.Visual Human-Machine Operation Interface

Equipped with touch screen HMI for one-key parameter setting, recipe storage for multiple bottle types, and real-time display of weighing data, production status and fault prompts.

■ Application

■ Customers

■ Exhibitions

■ Packaging & Delivery

Our machines is fully tested and calibrated before delivery.

It is packed in a strong wooden case with internal shockproof protection.

Various shipping options are available — by sea, air, or land — ensuring safe and on-time delivery by professional logistics partners.

TAGS