|| Product Introduction

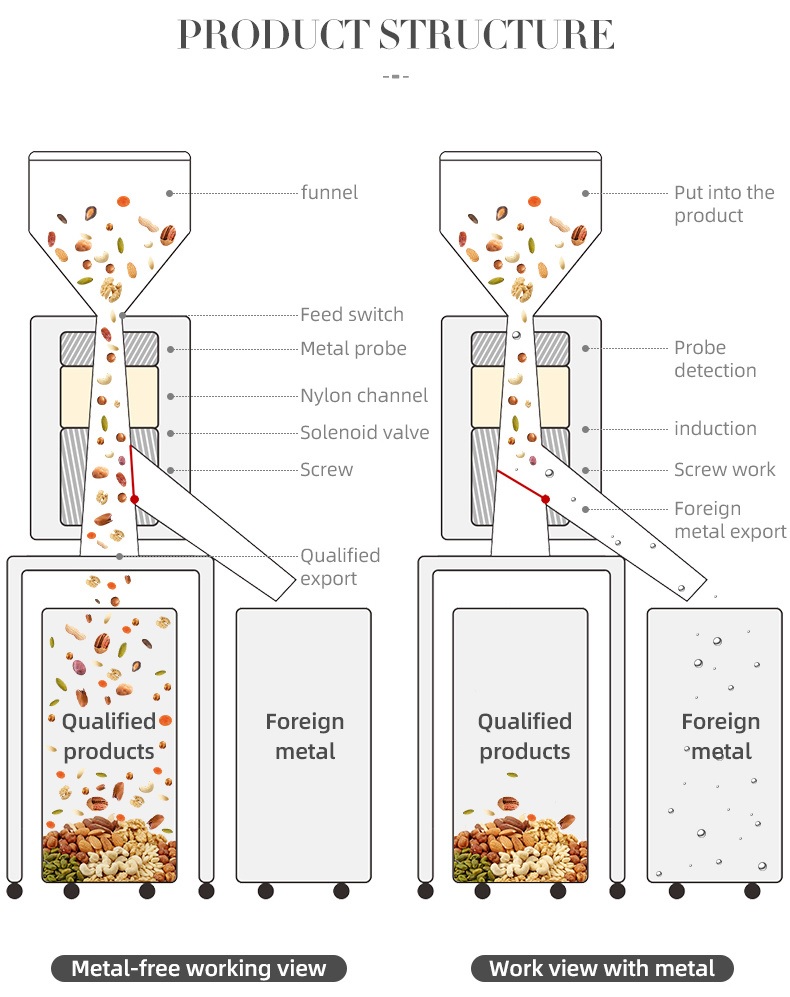

The Vertical Drop Metal Detector for Bulk Food is a vertically falling metal foreign object detection device specifically designed for bulk materials, powders, granules, and free-flowing foods. Installed at the material inlet of the production line, the equipment performs highly sensitive metal detection on the product during free fall, promptly identifying and removing foreign objects such as ferrous, non-ferrous, and stainless steel, thus improving food safety.

This compact and highly sensitive equipment is suitable for online foreign object detection in industries such as grains, nuts, coffee beans, flour, seasoning powders, sugars, spices, and additives.

|| Tech Specifications

Detection Method:Balanced coil

Sensitive adjustment:Automatic or Manual

Detection sensitivity: Fe: 0.5mm, stainless steel: 0.8mm(depend on product and speed)

Operation Panel:Key Pad

Material of Construction:304 Brushed stainless steel

Rejecting Mode:Sound and light alarm/Auto-Flap Rejector

Application:Ideal for pre-packaging inspection of bulk, powder and granule products

IP Rating:65

|| Main Features

1. Vertical Gravity Design

Utilizing the material’s falling motion for detection, this method is faster and has a higher throughput, offering superior performance for bulk foods compared to belt-driven structures.

2. High-Sensitivity Detection Coil

Employing digital signal processing (DSP) technology, it can detect ferrous, non-ferrous metals, and even difficult-to-detect stainless steel.

3. Automatic Rejection System

Equipped with a flip-plate rejection mechanism, it automatically and quickly rejects defective materials upon metal detection.

4. Adaptable to various pre-packaging processes

Suitable for detecting the feed inlet of powders, granules, and bulk foods; commonly used before packaging machines, bag-making machines, and weighing machines.

5. Dustproof and waterproof structure

The equipment can be equipped with IP65–IP66 protection ratings to meet stringent cleanliness requirements in food factories.

6. High-flow-rate detection capability

Can handle high-capacity, high-feed-rate materials without affecting overall production efficiency.

7. Intelligent operating system

Features automatic learning, product formula storage, sensitivity self-adaptation, and statistical output functions.

|| Application

|| Our Customers

|| Our Exhibitions

|| Packaging & Delivery

Our machines is fully tested and calibrated before delivery.

It is packed in a strong wooden case with internal shockproof protection.

Various shipping options are available — by sea, air, or land — ensuring safe and on-time delivery by professional logistics partners.

TAGS