■ Product Overview

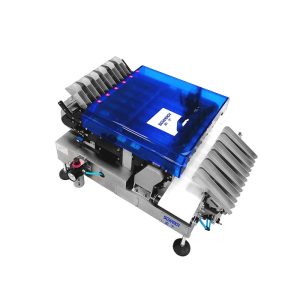

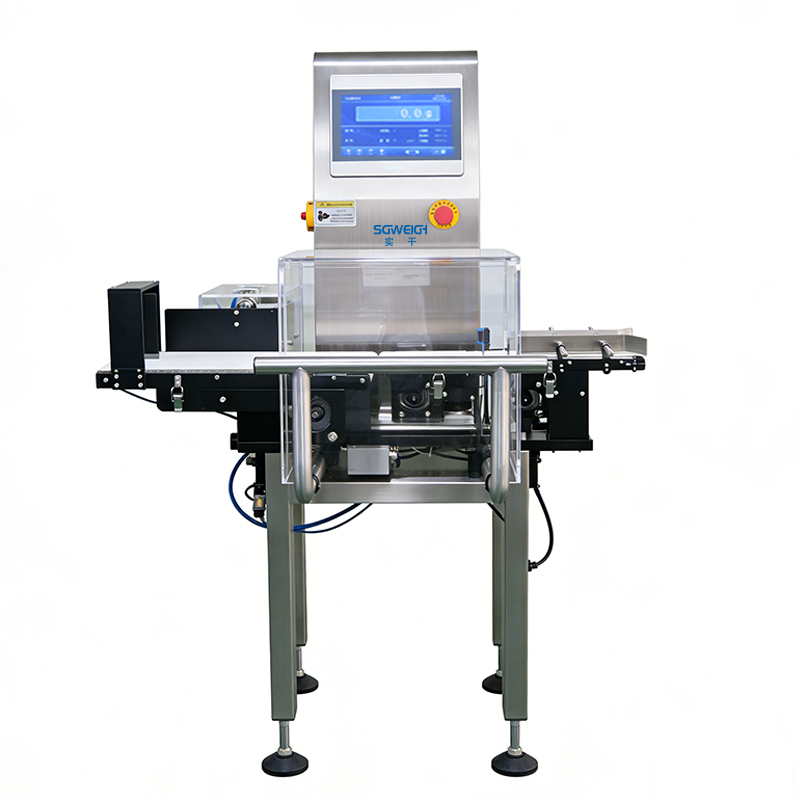

Conveyor Checkweigher with Diversion Rejection is a high-precision inline weighing system designed to automatically detect products with incorrect weight and divert them to a separate rejection lane without stopping production.Canned Food Conveyor Checkweigher is widely used in food, pharmaceutical, chemical, daily necessities and packaging industries where continuous, high-speed and accurate weight control is required.

Equipped with an industrial-grade load cell, stable conveyor system, and intelligent weighing algorithms, the checkweigher ensures real-time weight monitoring with excellent accuracy and repeatability. The diversion rejection mechanism (such as diverter flap, or multi-lane splitter) enables smooth separation of underweight, overweight, and defective items, minimizing production downtime and ensuring product quality consistency.

■ Tech Specifications

Type:SG-100

Weighing Range:2-300g

Limited of product:L:100 W:100 H:2-150mm

Accuracy:±0.05g Depend on products

Division Scale:0.01g

Belt Speed:0-90m/min

Max Speed:40-100 pcs/min

Belt Width:100mm

Machine Weight:70kg

Power Supply:AC 110/220V ±10% 50HZ

Power:100W

Main Material:SU304 stainless steel

■ Main Features

1. High-precision dynamic online weighing, real-time monitoring of the weight of each product.

2. Diversion-type rejection mechanism, gently diverting unqualified products.

3. Multiple rejection methods available: diversion baffle/push rod/multi-channel diversion.

4. Supports high-speed continuous production lines, rejection without shutdown.

5. Enables multi-level weight grading and product classification.

6. High-stability structure, reducing vibration and improving accuracy.

7. Flexible user interface, formula management, statistical analysis.

8. Powerful data interface, supporting intelligent production line operation.

9. Suitable for various product types including bagged, bottled, boxed, and palletized products.

10. 304/316 stainless steel construction, easy to clean and compliant with food and pharmaceutical standards.

■ Application

■ Customers

■ Exhibitions

■ Packaging & Delivery

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.

TAGS