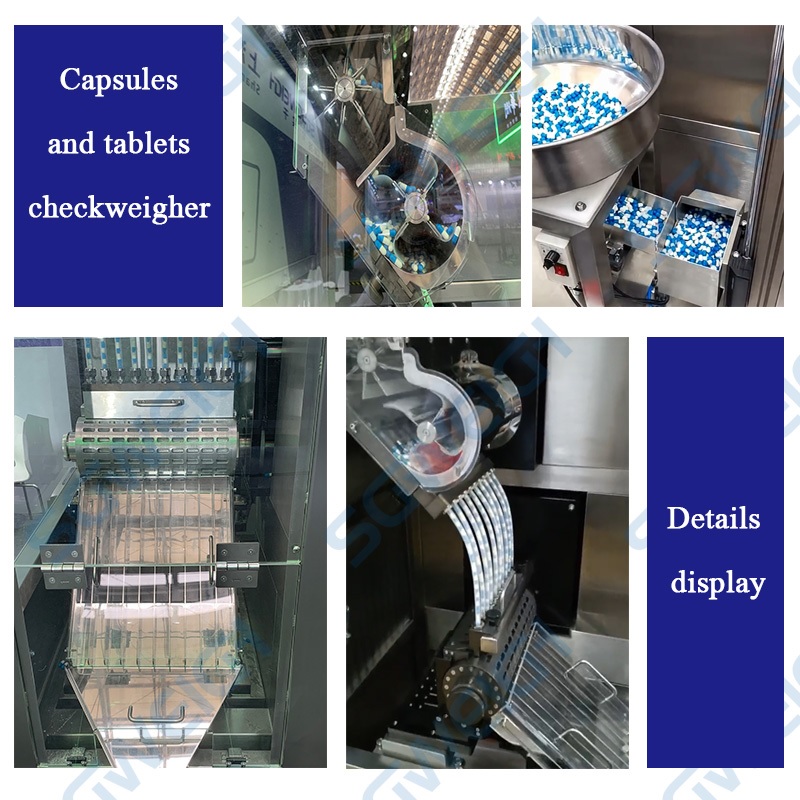

■ Product Introduction

The Capsule Tablet 20 lane Checkweigher is a high-speed, multi-channel dynamic weighing system specifically developed for the pharmaceutical industry. It enables high-precision weight inspection and sorting of small solid dosage forms such as capsules and tablets. The device utilizes a 10/20/30-channel parallel weighing structure, significantly improving inspection efficiency and making it suitable for high-volume continuous production lines.

■ Tech Specifications

Type:SG-JN20

Max throughput (10 lanes)100000 capsules/h

Max throughput (20 lanes)200,000 capsules/h

Max throughput (30 lanes)300,000 capsules/h

Weigh range:2-2000 mg

Highest sorting accuracy:±0.5mg

Scale interval:0.1 mg

Weight of Machine :350kg/500kg/700kg

Power supply:AC-220V±10%, 50HZ

Compressed air:0.3-0.9Mpa

■ Main Features

1. Multi-channel High-Speed Inspection

Equipped with 20 independent weighing channels, it can inspect 20 rows of capsules simultaneously, achieving high-speed batch inspection and significantly improving production efficiency.

2. High-Precision Weighing System

Utilizing imported high-sensitivity sensors and a high-speed sampling module, it achieves weighing accuracy down to the milligram level, ensuring accurate and reliable weight data for each capsule.

3. Intelligent Data Processing

A built-in high-speed DSP processor and automatic compensation algorithm correct for weighing deviations in real time, ensuring long-term stability and accuracy.

4. Flexible Rejection System

Each channel is equipped with an independent reject mechanism, quickly separating overweight, underweight, or empty capsules to ensure consistent yield and quality.

5. User-Friendly User Interface

The 10-inch touchscreen features an intuitive interface, supports Chinese and English language switching, and allows for recipe storage and one-touch parameter recall, ensuring easy operation.

6. Designed to Meet Pharmaceutical Standards

The entire machine is constructed of 304 stainless steel and food-grade contact materials, resulting in a compact, easy-to-clean design that complies with GMP and FDA standards.

7. Traceable Data Management

Supports weight recording, batch statistics, and abnormal alarm data export. It can be integrated with MES or ERP systems for production traceability and quality control.

8. Modular Design

Each inspection module can be independently maintained and replaced, reducing downtime and improving equipment operational stability.

9. Compatible with Various Capsules

It can be used to inspect hard capsules, soft capsules, and tablets of varying sizes, allowing for quick product switching by replacing the guide rails.

10. Customizable Expansion

The number of lanes, rejection methods, and external interfaces can be customized to meet production line requirements, enabling seamless integration with upstream filling or downstream packaging machines.

■ Application

20-column Capsule Checkweigher is widely used in pharmaceutical production lines such as capsules, tablets, and granules, providing companies with high-efficiency, high-precision, and intelligent weight quality control solutions.

■ Customers

■ Exhibitions

■ Packaging & Delivery

● Our machines undergo comprehensive testing and commissioning before shipment to ensure stable and reliable performance.

● Equipment is packaged in thickened wooden crates with shock and moisture-proof interiors to effectively prevent damage during transportation.

● We partner with several professional international logistics companies and support a variety of shipping methods, including sea, air, and land transport.

● Ensure the equipment arrives safely and on time at your facility.

TAGS