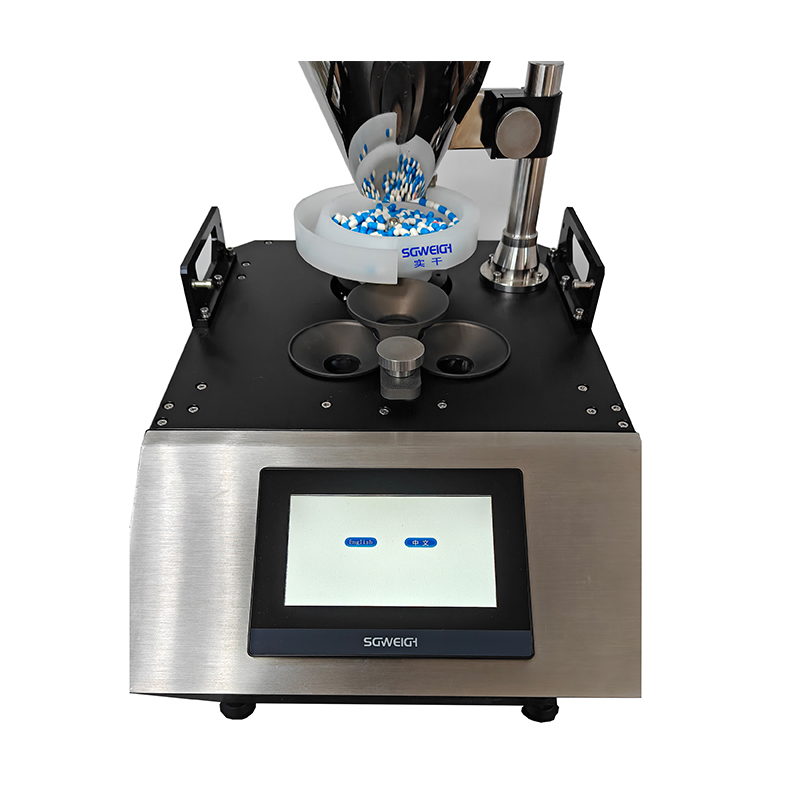

■ Product Introduction

The Small Size Tablet Sampling Checkweigher is a precision instrument specially used to detect the weight of capsules and tablets.Weight Inspection Machine is widely used in the pharmaceutical, health care products and other industries to ensure that the weight of each capsule or tablet meets the standard.

■ Tech Specifications

Type:SG-CJ1

Output:up to 60 pcs / min

Display scale:0.1mg

Highest accuracy:±1mg(Depend on products)

1.It can detect all types of capsules such as 000#, 00#, 0#, 1#, 2#, 3#, 4#, 5#, SA, SB, and conventional tablets.

2.Weighing range:0-2000mg.

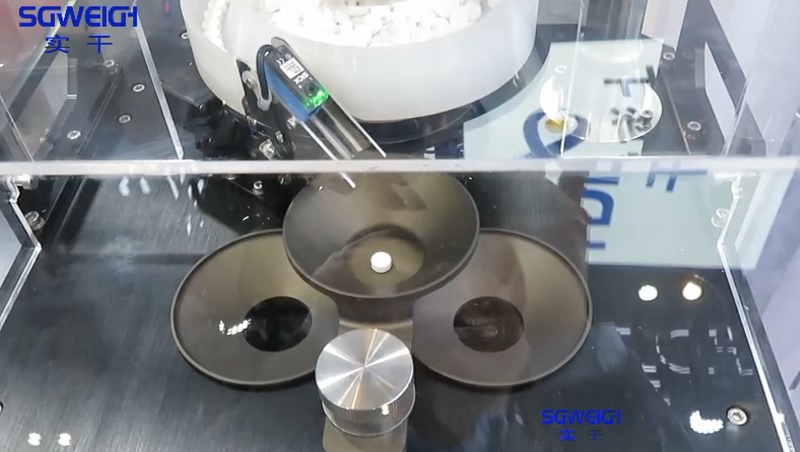

3.Power supply:220V,50HZ.

4.7-inch resistive touch screen.

5.One-touch automatic calibration function, built-in E-grade stainless steel weights.

6.Support communication interfaces RS-232, RS485, Mudbus-TCP communication protocols, USB and Ethernet.

7.Automatic cleaning at startup, manual zeroing, data clearing.

8.Sensor overload protection, AD separation mode.

9.The material contact part is stainless steel, or hardened anti-corrosion treatment, which will not cause drug contamination.

10.Sudden power failure self-protection to prevent data loss.

11.Counting function, timely understanding of the weighing quantity.

12.Support power supply voltage customization to meet foreign power supply.

13.One-touch automatic zeroing function, zero point tracking.

■ Main Features

1: Adopting German advanced technology high-precision ten-thousandth balance weighing unit, unique dynamic filtering algorithm with the highest accuracy of plus or minus 1mg (depending on the material) for high-speed and stable weighing.

2: Weight-free internal automatic calibration function, built-in E-level high-precision weights for one-button automatic calibration, no need to manually place weights for calibration.

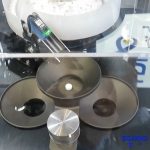

3: The weighing sensor is designed to be free of powder accumulation to avoid errors caused by long-term capsule or tablet weighing on the weighing platform.

4: The weighing sensor deformation protection device can bear 500% destructive overload to prevent sensor damage due to overload.

5: The mold is hardened for corrosion resistance, and the drug contact surface is made of stainless steel 316, which meets the requirements of drug contact without pollution.

6: Timed weighing self-check function, which allows the equipment to automatically detect the accuracy of the sensor accuracy at regular intervals to ensure the accuracy of the machine operation at all times.

7: The static weighing method of tablets and capsules avoids the vibration and wind resistance interference caused by the movement of tablets and capsules to ensure more stable weighing, making it weigh at the highest precision of 1mg.

8: The operation interface is simple and easy to understand, and the weighing data BOM table function can be exported with one click on the USB flash drive for data analysis.

9: The product runs without noise, with a full servo drive structure and a dead angle design for the whole machine, so you can clearly see the movement trajectory of each capsule or tablet being sorted.

10: Power-off protection function, data will not be lost, and undetected capsules or tablets will not be missed or misdetected.

11: The whole machine is modularly designed, equipment failures can be discovered in time,and it is convenient for overhaul and daily maintenance.

■ Application

■ Customers

■ Exhibitions

■ Package & Shipping

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.

TAGS

4-Line Dynamic Check Weigher

Glass Bottle Turntable Checkweigher

Inline Production Combi Metal Detector and Checkweigher

High Throughput Advanced Pharma Metal Detectors