■ Product Introduction

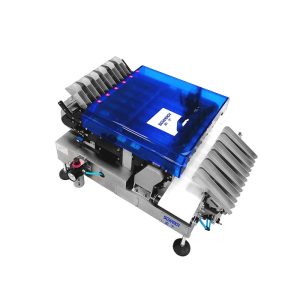

Integrated Metal Detection and Checkweigher System creates a powerful critical control point solution in one space-saving device. The checkweigher measures product weights quickly and precisely-rejecting “out of tolerance” products, while the metal detector consistently detects and rejects contaminated products.

Combi Metal Detector and Checkweigher

■ Tech Specifications

Model: SG-JS150

Detection hole width: 150mm

Detection hole height: 100-200mm

Detection sensitivity:

H-100mm: Fe≥Φ0.8mm,SUS≥Φ1.2mm

H-120mm: Fe≥Φ0.8mm,SUS≥Φ1.8mm

H-150mm: Fe≥Φ1.2mm,SUS≥Φ2.0mm

H-200mm: Fe≥Φ1.5mm,SUS≥Φ2.5mm

Weighing range: 5-500g

Weighing accuracy: ±0.1g(Depends on products)

Conveyor belt height: 750mm (±50mm)

Conveying capacity: 10Kg/time

Delivery direction: from left to right

Maximum speed of conveyor belt: 25m/min

Conveyor belt material: food grade PU belt

Protection class: IP65

Display and operation mode: LED LCD flat button input

Machine weight: 240kg

Power requirements: AC220V 50HZ

Power: 300W

Dimensions: about L2267×W589×H1500mm (final design shall prevail)

■ Main Features

1.Simultaneously checks product weight and detects metal contaminants, optimizing space and efficiency.

2.Can record parameters of 100 different products.

3.Based on adaptable DDS and DSP technology, they can improve detection sensitivity and stability.

4.Wide range of checkweigher belt widths and lengths to fit your production line

5.Dual rejecters separating foreign objects from over/ under weights to facilitate root cause problem determination and action

■ Application

■ Customers

■ Exhibitions

■ Package & Shipping

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.

■ FAQ

Q1. Are you a manufacturer or trader?

A: We are a manufacturer and we are located in Shanghai,China. We have our own design team for product design.

Q2: Can you explain the whole transaction process?

- Understand the specific needs of customers and determine the machine details.

- Sign the contract.

- Pay the deposit.

- The factory arranges production.

- Test and inspect the machine before shipment.

- Check by customers through online or on-site testing.

- Shipment and transportation, balance payment.

Q3.How much does Conveyor Metal Detector cost?

There is no quick, easy answer to this question.Our machine is specific to the customer, so arriving at ‘standard pricing’ isn’t usually practical. Pricing largely depends upon your unique needs, such as the products you want to detect, the size of the product,the speed you want to achieve,or the complexity of the process. Contact us to get a specific quote.

Q4. What kind of shipping method can you provide?

A: By sea, by air and by international express.We will send the photo and video of machine to customer to check the machine running situation before delivery.

Q5. Do you accept customer logo and customization?

A: We accept all kinds of customization and logo for our customers for all our products.

Q6. How about the packing for product? Is it easy damaged during transportation?

A: No.We takes of wooden case and it is very safe.

TAGS

Inclined Conveyor Metal Detector

Professional Tablet Capsule Metal Detector

Inline Capsule Pharmaceutical Checkweigher

Online 10 Lines Checkweigher for Liquid Stick Pouches