■ Product Introduction

Quality Conveyor Metal Detector is a type of machine used primarily to detect metal in products in the food industry.Metal Detectors for Food and Nutraceutical Production protect equipment and regulate compliance in the food industry.Contaminated products can be removed from the production line, ensuring that contaminants do not reach consumers.

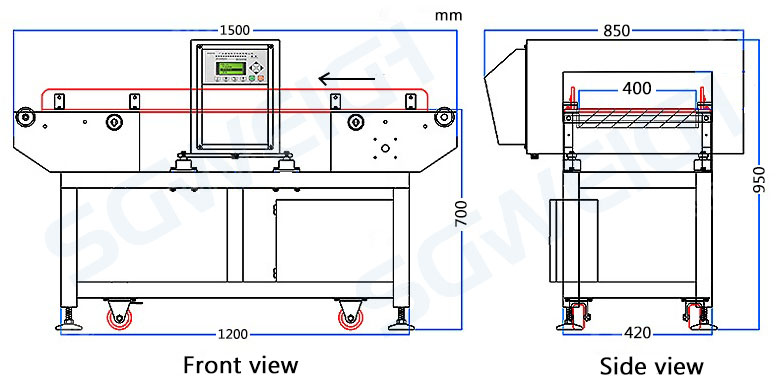

■ Tech Specifications

Detection sensitivity: in empty state

H-100mm: Fe≥Φ0.8mm, Non-Fe≥Φ1.5mm, SUS≥Φ1.5mm

H-120mm: Fe≥Φ0.8mm, Non-Fe≥Φ1.5mm, SUS≥Φ2.0mm

H-150mm: Fe≥Φ1.0mm, Non-Fe≥Φ1.5mm, SUS≥Φ2.0mm

H-200mm: Fe≥Φ1.2mm, Non-Fe≥Φ2.0mm, SUS≥Φ2.5mm

Effective detection hole width: 150-1000mm customized according to requirements

Effective detection hole height: 80-500mm customized according to requirements

Maximum speed of conveyor belt: 25m/min

Conveyor belt material: food grade PU belt

Protection class: IP65

Display and operation mode: LED fast key input

Machine weight: about 120kg

Power requirements: AC220V 50HZ

Power: 200W

■ Main Features

1. Excellent stability and sensitivity.

2. Suitable for all metals, including ferrous metals, copper, stainless steel, etc.

3. Dust-proof and waterproof stainless steel structure.

4. Can be equipped with a variety of integrated rejector styles (push rod type, flap type, jet type, etc.).

5. Safeguard processing and packaging lines.

6. Protect your brand and maintain your reputation.

■ Application

■ Customers

■ Exhibitions

■ Package & Shipping

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.